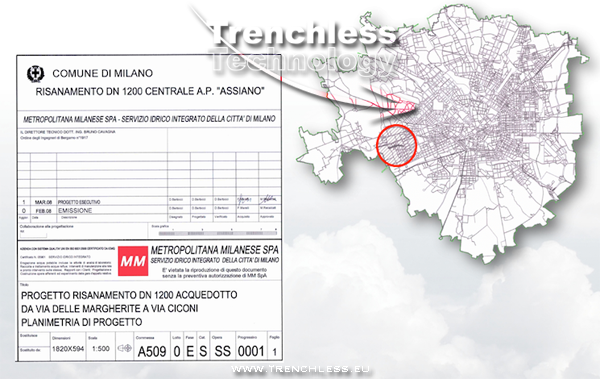

Client: IN.TEC. Srl – Italy

Year: 2008-2010

What I did: I performed the development of proprietary technology applications; strategic marketing & technical-commercial communication.

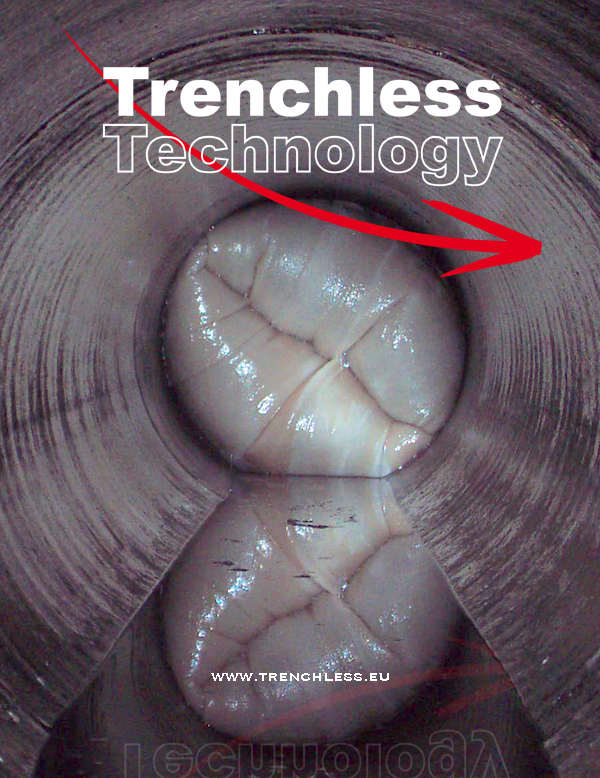

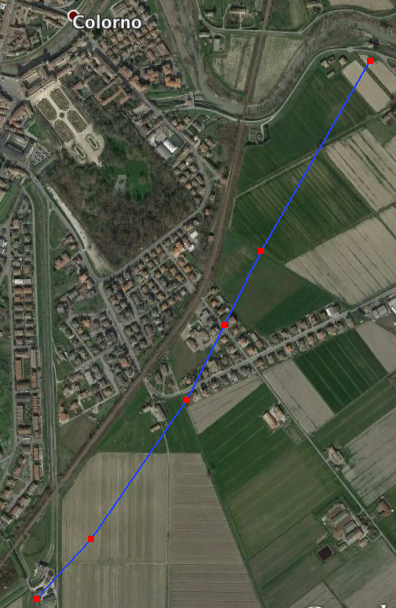

click the image above to open a technical note about IN.TEC. peculiar technologies.

Related documents:

- Tecniche di risanamento non distruttivo delle tubazioni interne degli edifici – Noi Geometri – July-08, Italy

- Il No-Dig in verticale – Servizi a Rete n. 1 – January-09, Italy

- Video IN.TEC. Technology [youtube]