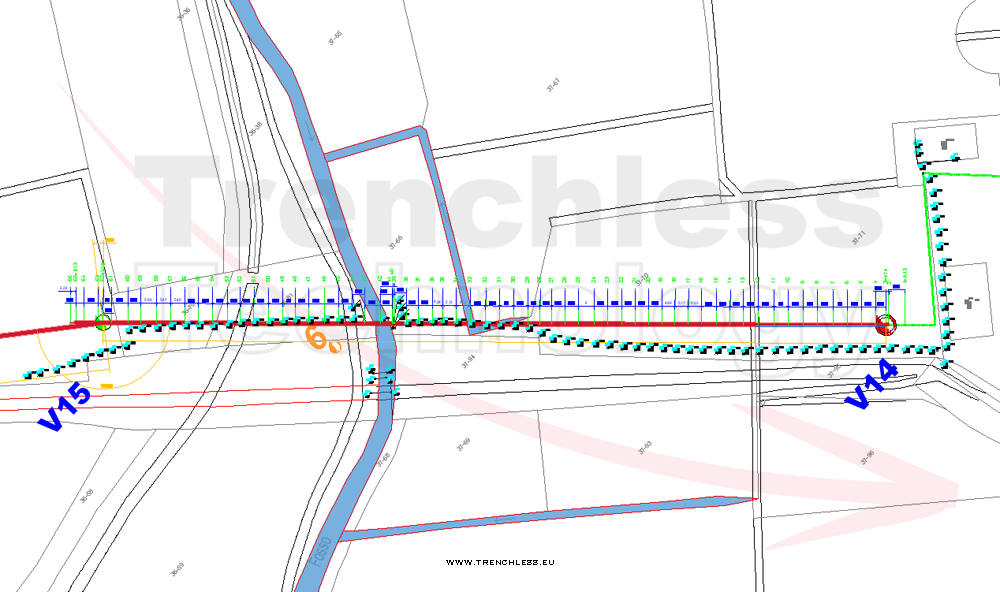

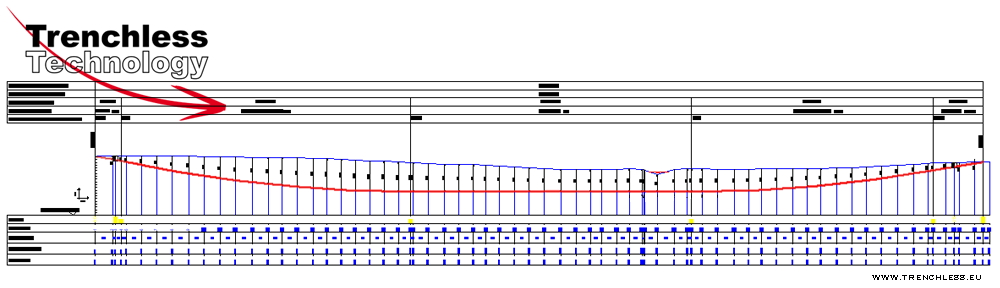

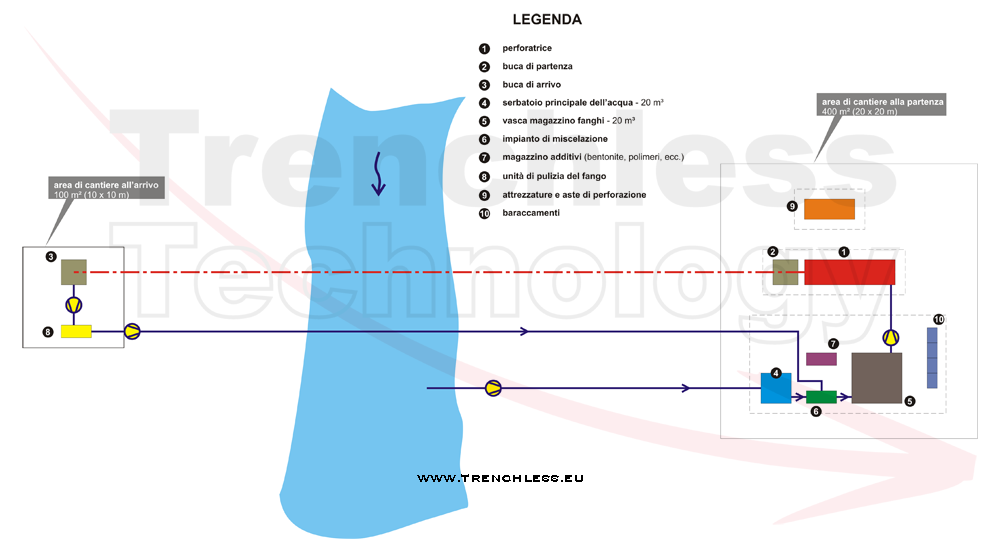

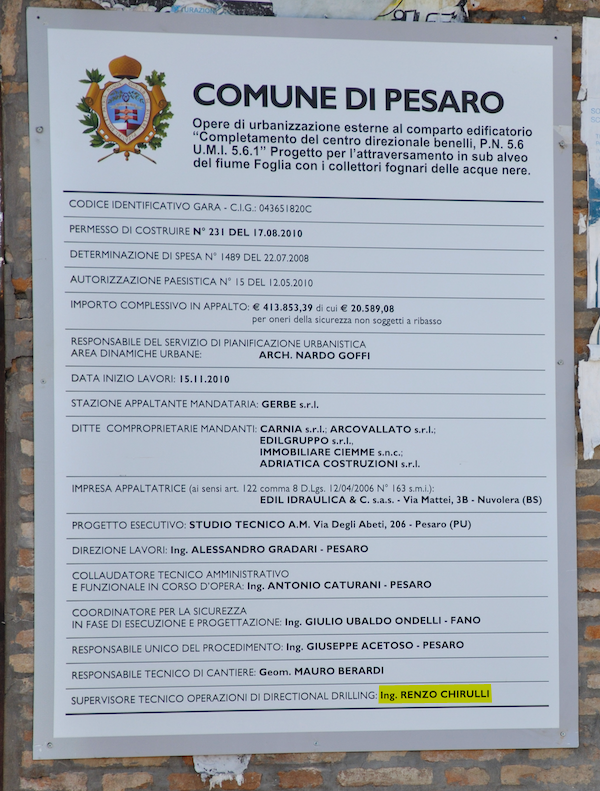

Client: EUROSCAVI Srl – Italy

Year: 2016

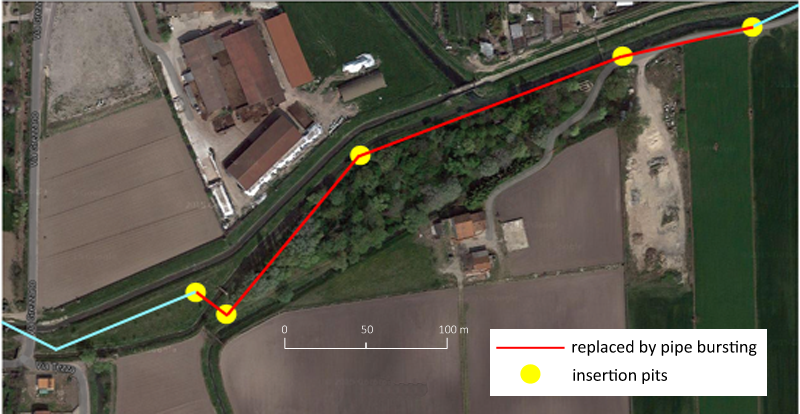

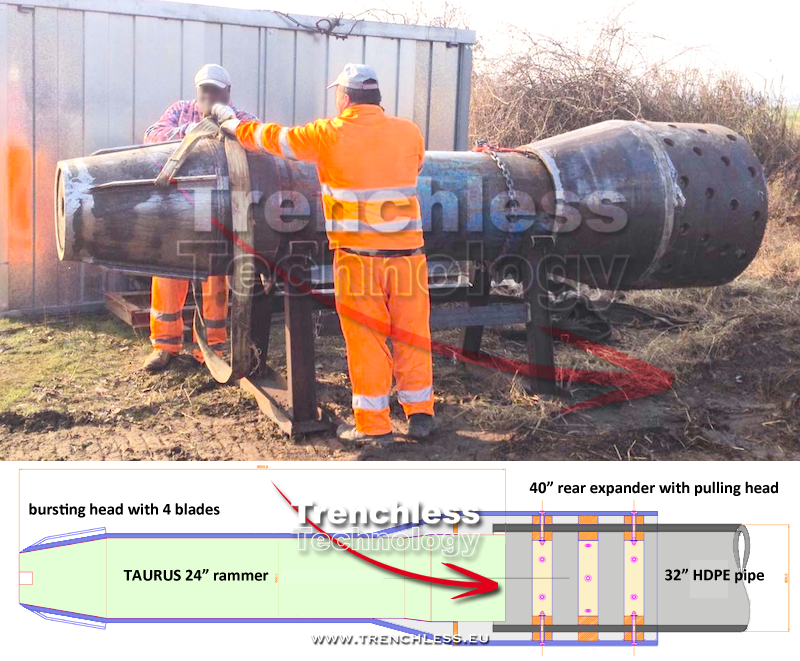

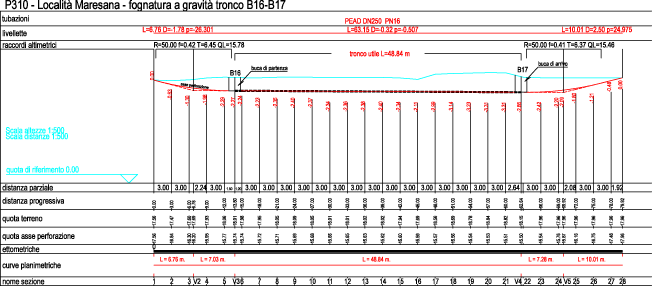

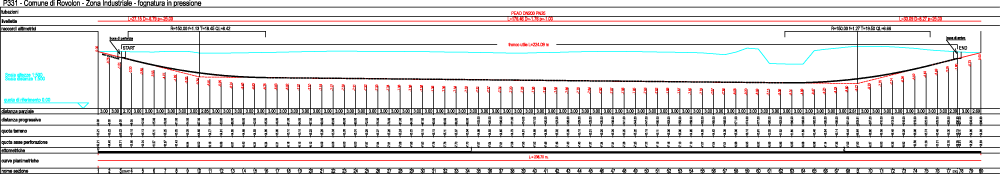

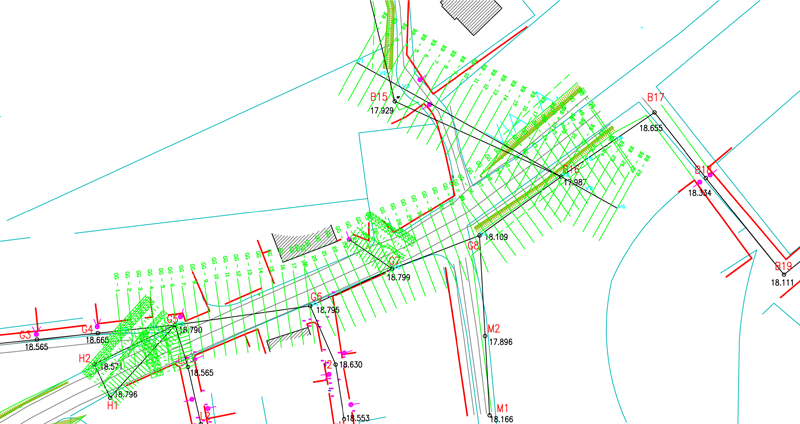

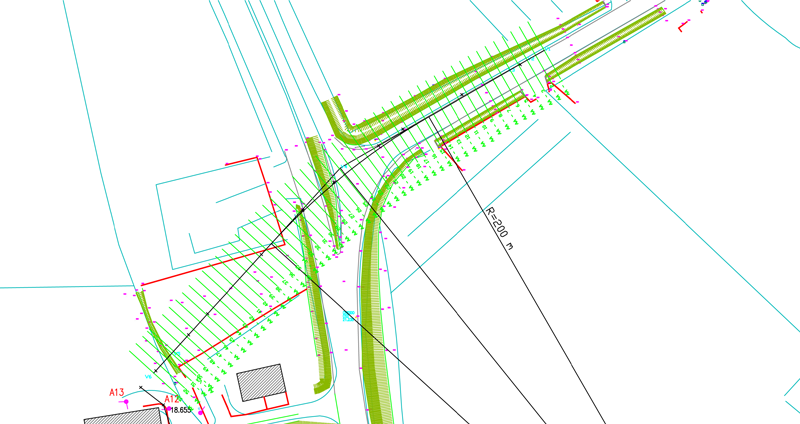

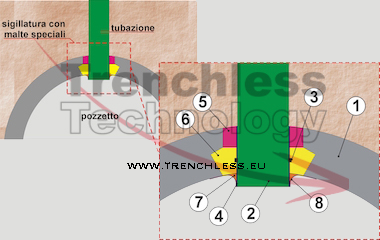

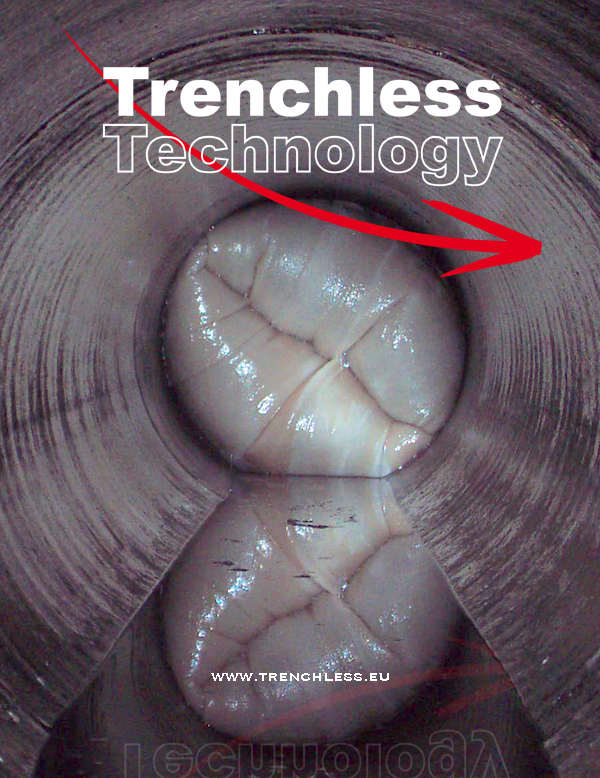

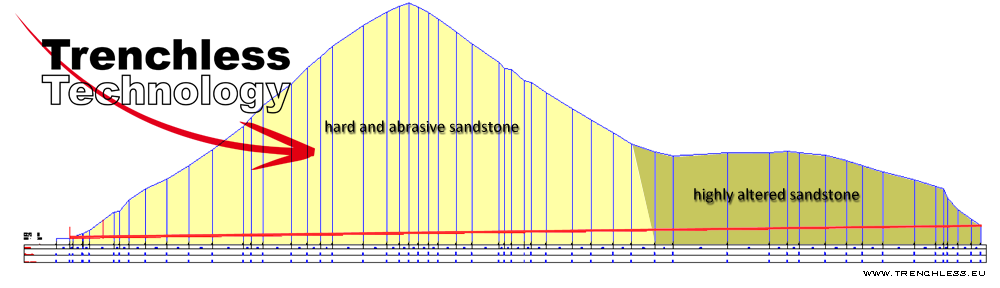

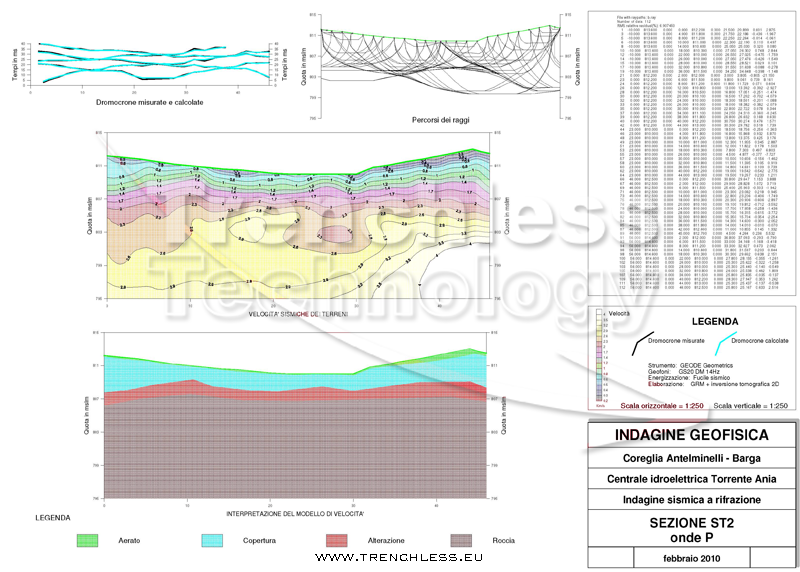

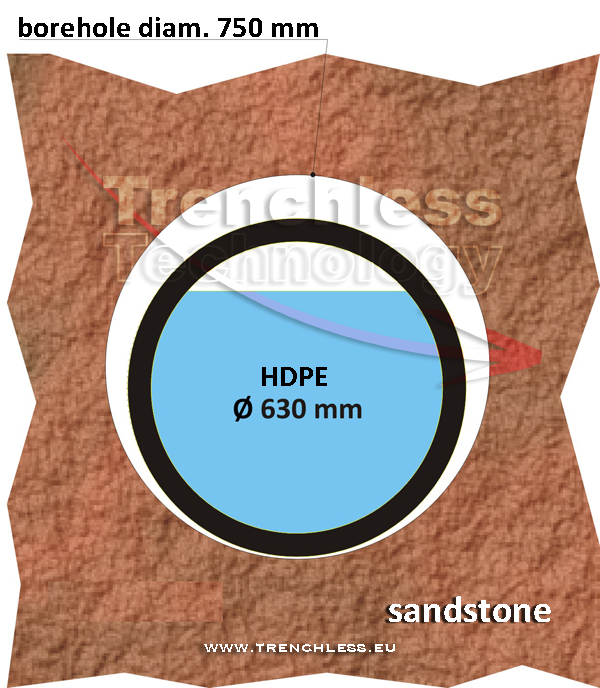

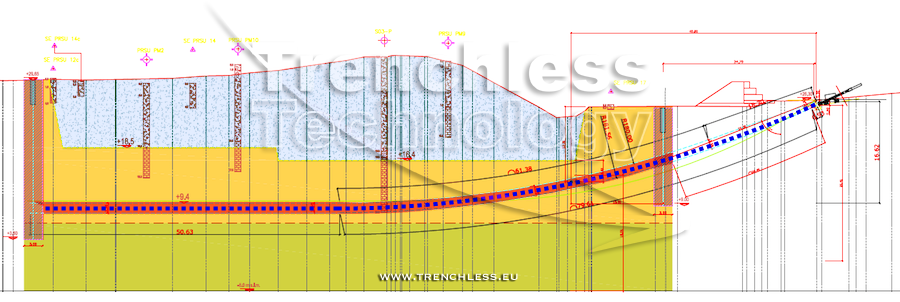

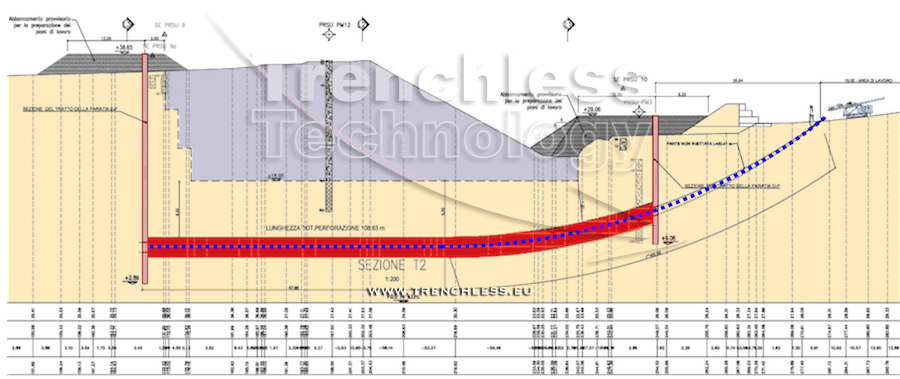

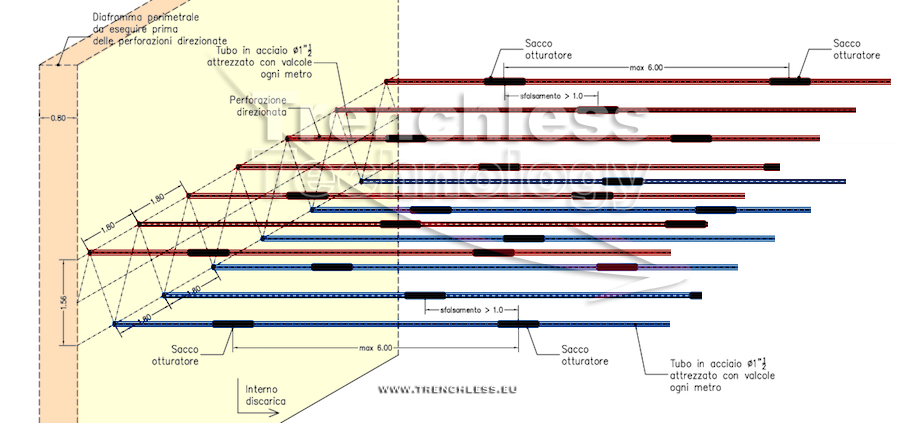

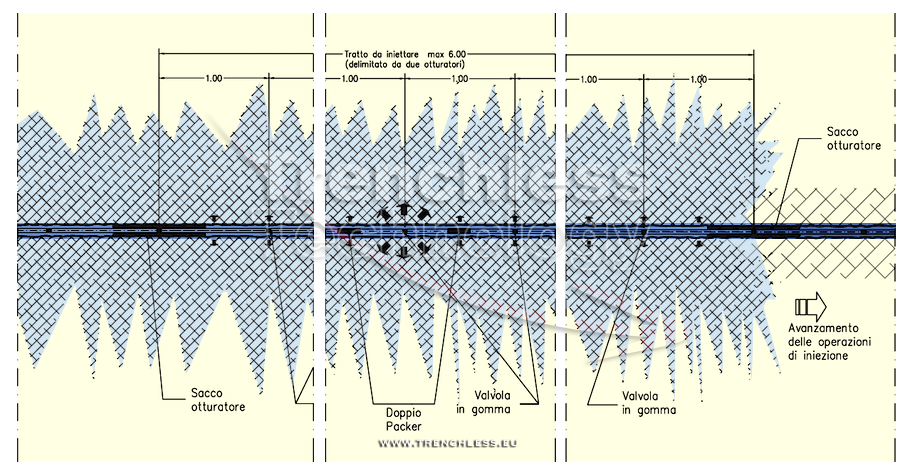

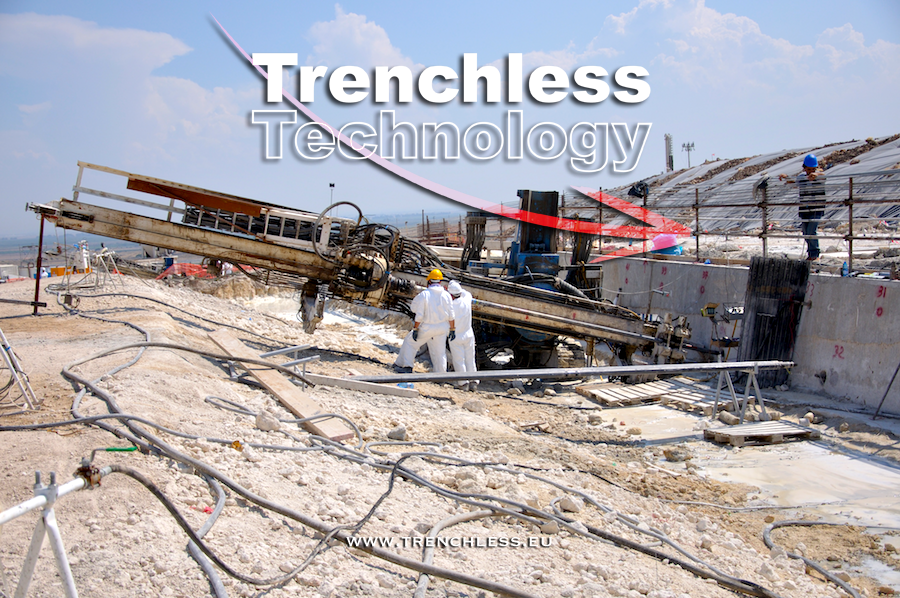

What I did: I made the detailed design of the replacement by dynamic pipe bursting of a DN600 (24″) sewer concrete pipe with a DN800 (32″) HDPE pipe; I coordinated all the geological/geotechnical preliminary survey and I also made the detailed design of the bursting-expanding head, tailored shaped to work with a Tracto Technik TAURUS rammer (24″). The expander has an outside diameter of 1000 mm. The soil was sand with coarse to very coarse gravel.

Related documents:

- Tecnologie innovative a basso impatto ambientale per l’installazione, il risanamento e la sostituzione di reti idriche e fognarie: Il No-Dig – Atti del Convegno “Mercato dell’Acqua” – Istituto Internazionale di Ricerca, Milano, 13-Nov-03 – Italy

- Tecnologie no-dig: eliminazione o limitazione degli scavi a cielo aperto ed abbattimento dei costi indiretti generalizzati nelle operazioni di installazione, risanamento e sostituzione di tubazioni fognarie” – Atti della Giornata di Studio su “Impatto sull’ambiente dei materiali utilizzati per le condotte” – Università Milano Bicocca, Milano, 26-Nov-10 – Italy

- Tecnologie no-dig: la sostituzione senza scavi a cielo aperto delle tubazioni interrate – Atti del corso STADIUM 2012 “l’Acqua e le Smart Cities” – Politecnico di Milano, 21-Mar-12 – Italy