The loose-fit lining (LFL) technique merely involves the insertion into the host pipe of a new pipe (made of plastic, steel, clay or GRP), whose outer diameter is smaller than the inner diameter of the host pipe.

The annular space existing between the outer walls of the new pipe and the inner walls of the host pipe is called annulus. Its width can vary between as little as a few millimetres to some centimetres, according to the technique used.

Another term used to describe these technologies is, in specialised technical language, sliplining, as the liner is either pushed, but more often pulled, into the host pipe.

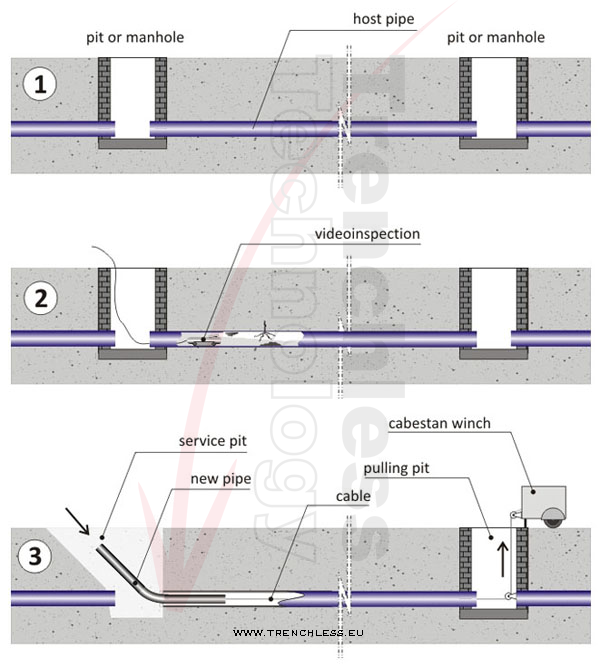

Loose-Fit Lining operational stages

DIMENSIONAL RANGES AND MATERIALS

-

ANY MATERIAL.

-

LENGTH RANGES from 5 M (15 FT) UP TO 1.000 M (3.300 FT) PER SHOOT

-

DIAMETER RANGES from 50 MM (2 IN) TO 2.500 MM (98 IN)

If you are interested in Loose-Fit Lining you will find of interest the following case history:

You can also find articles and papers related to Loose-Fit Lining in the following sections of the website: