Ductile materials like steel or plastic can replaced by splitting (pipe splitting) the old pipe while inserting the new one. This replacement technology is called pipe splitting.

The new pipe can be made of HDPE, PVC, cast iron, PP or steel, having the outside diameter 30% or 50% larger than the diameter of the replaced old pipe.

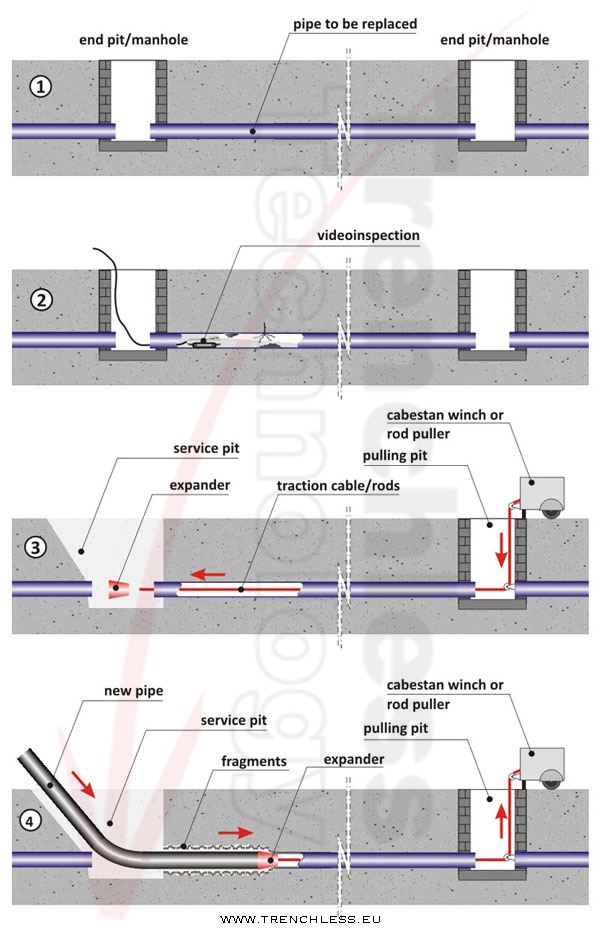

Pipe splitting is normally performed by pulling back a splitter equipped with one or more blades, followed by an expander that diverts the host pipe once split.

pipe splitting method has the same stages like pipe bursting

DIMENSIONAL RANGES AND MATERIALS

-

steel, plastic.

-

LENGTH RANGES from 5 M (15 FT) UP TO 300 M (1.000 FT)

-

DIAMETER RANGES from 50 MM (2 IN) TO 1.000 MM (40 IN)

If you are interested in Pipe Splitting you will find of interest the following case history (about pipe bursting):

- PIPE BURSTING AND UV-CIPP AT THE FLORENCE AMERICAN CEMETERY OF THE WWII

- LARGE DIAMETER DYNAMIC PIPE BURSTING FOR SEWER REPLACEMENT

You can also find articles and papers related to Pipe Splitting in the following sections of the website: