https://www.linkedin.com/pulse/reflow-looking-partners-renzo-chirulli

ReFlow (patent pending), an original idea developed by Renzo Chirulli and Manuel García Román (University of La Laguna, Tenerife – Spain), was selected to be between the three finalists of IWATER Idea Awards 2016, held in Barcelona, Spain on 15-17 November 2016.

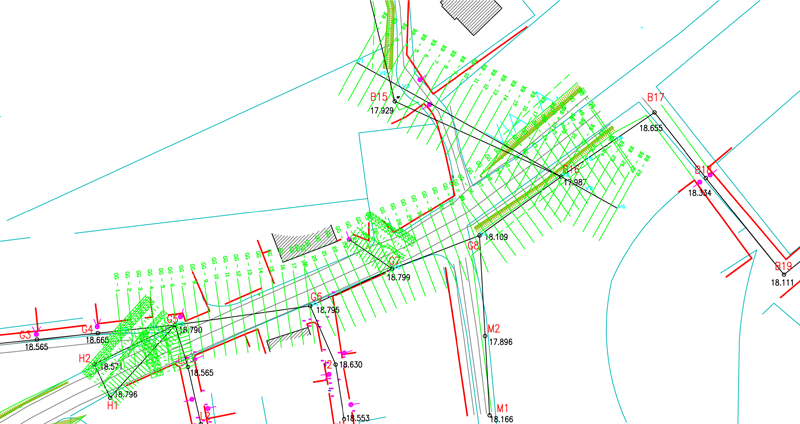

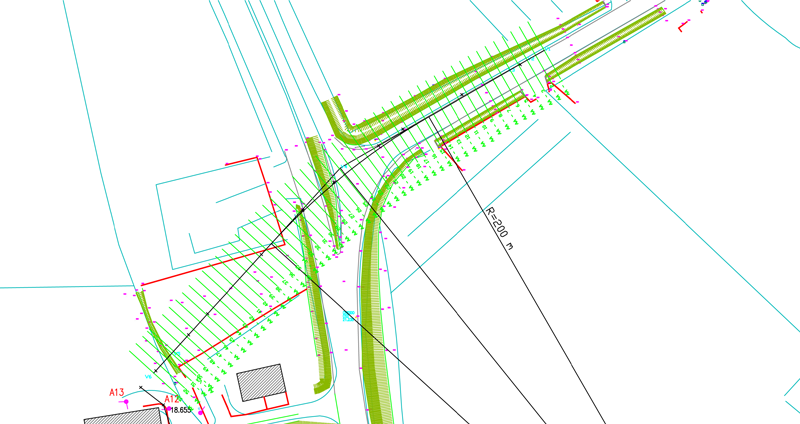

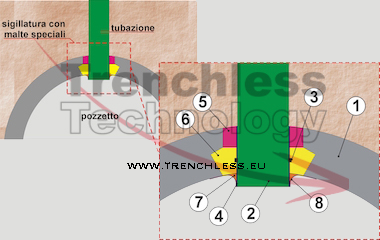

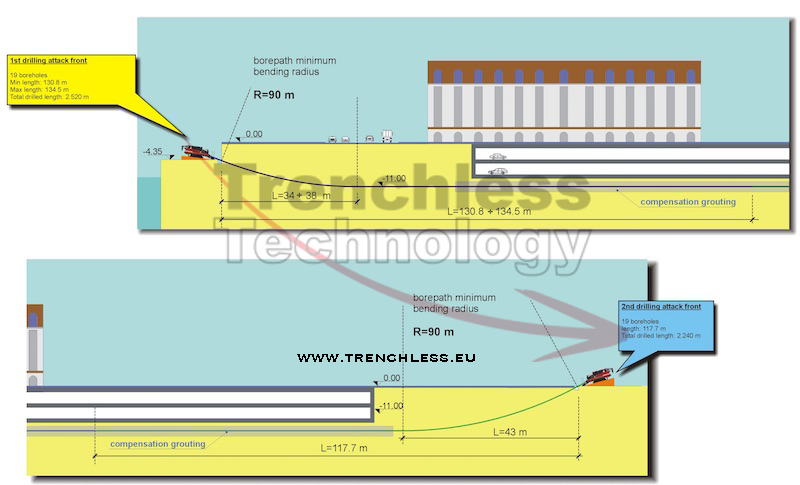

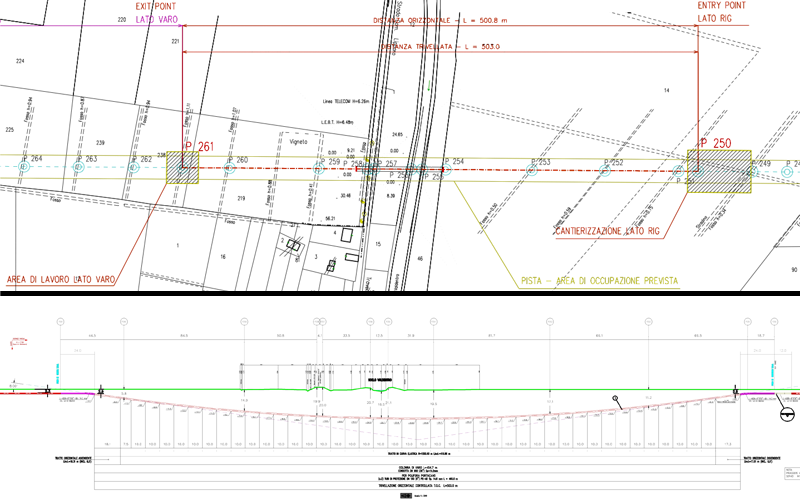

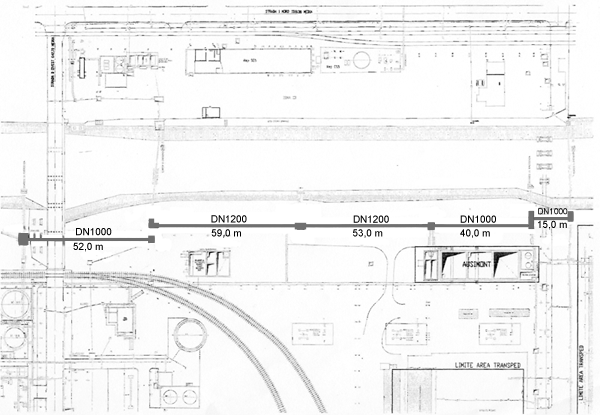

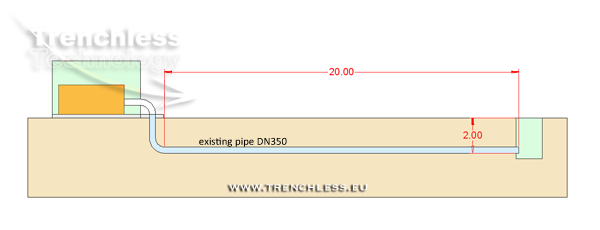

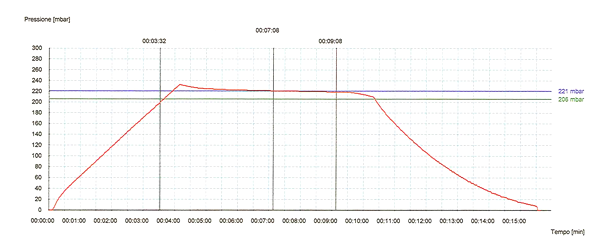

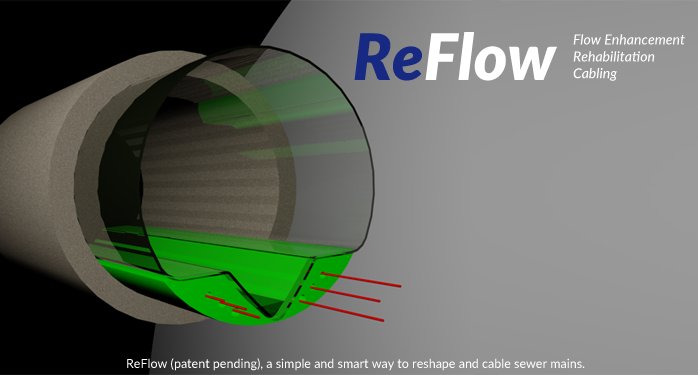

ReFlow – Flow Enhancement, Rehabilitation and Cabling is a modular mold that allows to reshape existing sewer conduits, migrating from a traditional circular or egg-shaped cross section to an algebraic curve of degree higher than two (i.e. Bernoulli’s lemniscate or Huygens lemniscate). The resulting reshaped cross section significantly increments fluid velocity at the lowest flow rates. Low flow rates in sewage pipes cause sedimentation of solids and other problems derived from the lack of water aeration and generation of hydrogen sulfide, namely metal corrosion and concrete attack by sulfate. The new reshaped pipe invert is obtained by assembling several molds, manhole to manhole, in a continue string, before carrying out a trenchless relining operation (i.e. Cured In Place Pipe). The new liner, installed by a trenchless method, takes the shape resulting from the combination of the existing pipe and the ReFlow mold, as shown below.

ReFlow does not enhance merely hydraulic performances, it allows to construct several secondary conduits, obtained in the body of the mold string. The new conduits result to be parallel to the pipe axis and perfectly protected against the most common attacks (fluid dragging, mice, etc.). These secondary conduits can be used to install fiber optic cables, transforming the sewer main in a telecommunication infrastructure.

ReFlow is a simple and smart way to solve common problems due to low fluid velocity at low flow rates, such as sedimentation and hydrogen sulfide and for cabling a sewer main before rehabilitate it with the most popular trenchless methods.