Pipes made of rigid materials, like concrete, clay, cast iron, can be replaced, without open trenches, by bursting the existing pipe while inserting the new one. This replacement technology is called pipe bursting (also known as pipe cracking or berstlining).

The new pipe can be made of HDPE, PVC, ductile iron, PP or steel, having the outside diameter 30% or 50% larger than the diameter of the replaced old pipe.

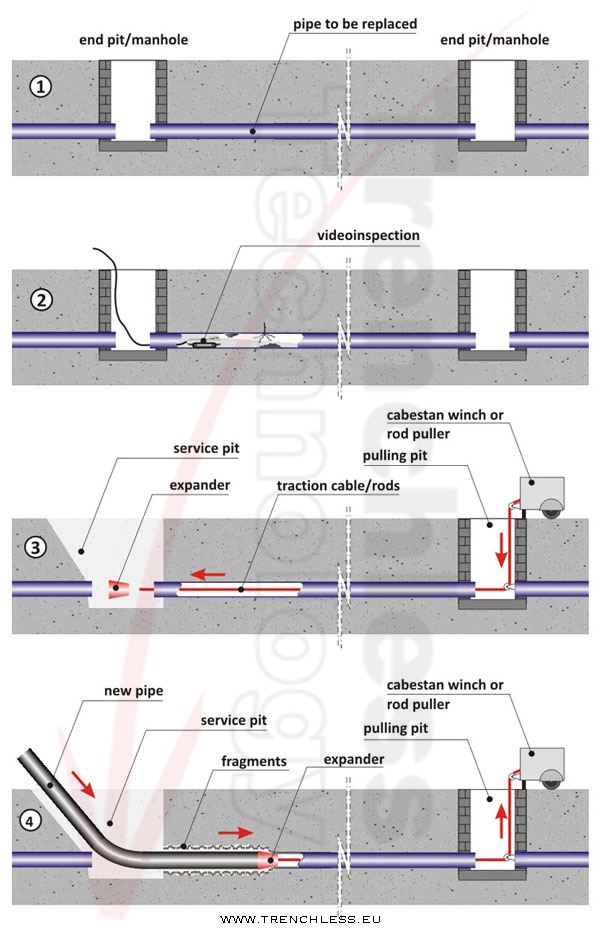

Pipe busting can be performed according three different techniques:

- static pipe bursting, by using rod pulling machines;

- dynamic pipe bursting, by using pneumatic or hydraulic rammers;

- pipe bursting with hydraulic expanders.

Static and dynamic pipe bursting are the most common no-dig replacement methods for rigid pipes.

pipe bursting stages.

DIMENSIONAL RANGES AND MATERIALS

-

concrete, cast iron, clay, asbestos cement.

-

LENGTH RANGES from 5 M (15 FT) UP TO 300 M (1.000 FT)

-

DIAMETER RANGES from 50 MM (2 IN) TO 1.800 MM (72 IN)

If you are interested in Pipe Bursting you will find of interest the following case history:

- PIPE BURSTING AND UV-CIPP AT THE FLORENCE AMERICAN CEMETERY OF THE WWII

- LARGE DIAMETER DYNAMIC PIPE BURSTING FOR SEWER REPLACEMENT

You can also find articles and papers related to Pipe Bursting in the following sections of the website: