Cement Mortar Lining (CML) is specifically conceived for rehabilitating steel and cast iron pipes designed for the transportation of water, whether drinkable, industrial or marine.

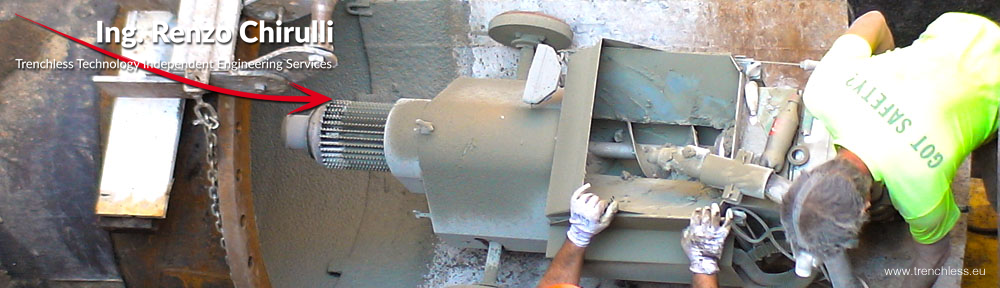

It consists in the application, through a high-speed centrifugal process, of cement mortar (of even thickness) to the inside wall of the pipes that need to be rehabilitated.

It is the first no-dig technique ever to be standardised (in the Usa in 1939) and since then has been applied worldwide for rehabilitating waterworks, water transportation systems for agricultural use, fire-fighting plants, and, on occasion, also for treating pipelines designed for discharging industrial waters or sewers.

This technique, with appropriate formulations of the mortar, can be used also to rehabilitate pipelines for the transportation of crude oil and fuel.

The thickness of the layer of the mortar can vary from 6 to 14 mm, according to need. This layer, besides protecting the internal surface of the pipe from corrosion, occludes the holes that can be present in the pipe, restoring its waterproofing. It is in fact mainly used in rehabilitating aqueducts suffering from widespread leaks.

the lining machine working inside a DN1200 steel pipe

DIMENSIONAL RANGES AND MATERIALS

-

steel and cast iron.

-

LENGTH RANGES from 5 M (15 FT) UP TO 500 M (1.650 FT) PER SHOOT

-

DIAMETER RANGES from 80 MM (3,5 IN) TO 5.000 MM (200 IN)

If you are interested in CML you will find of interest the following case history:

You can also find articles and papers related to CML in the following sections of the website: