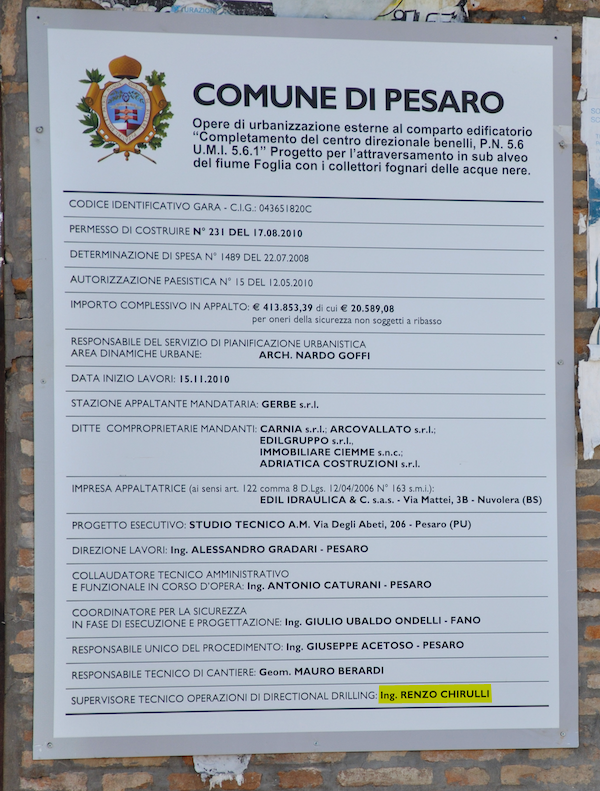

Client: SE.T.A. Srl (today ETRA Spa) – Italy

Year: 2003-2004

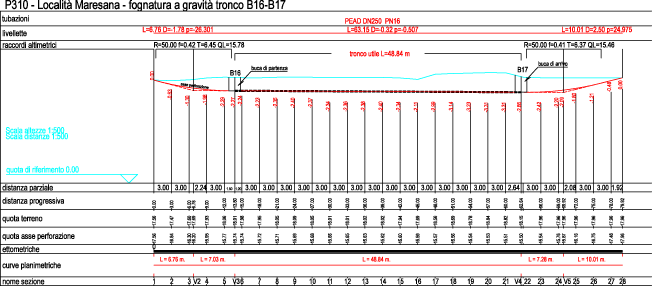

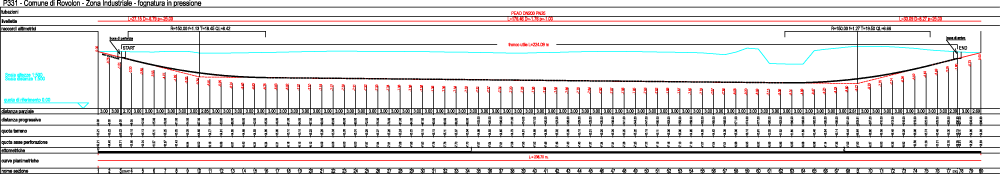

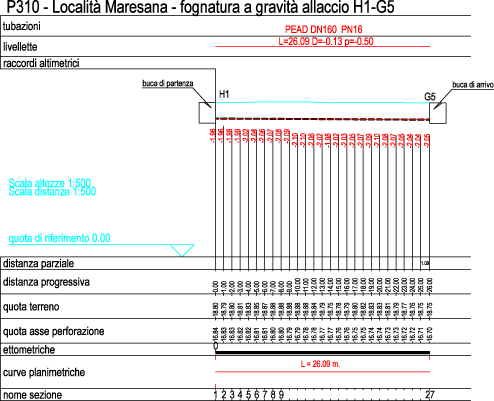

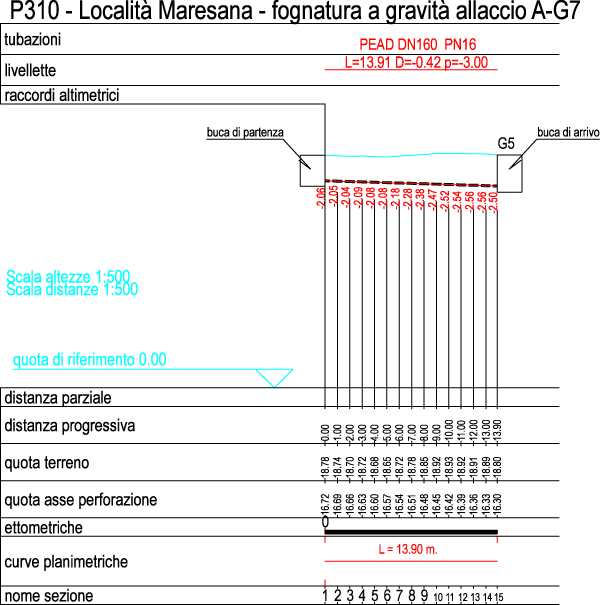

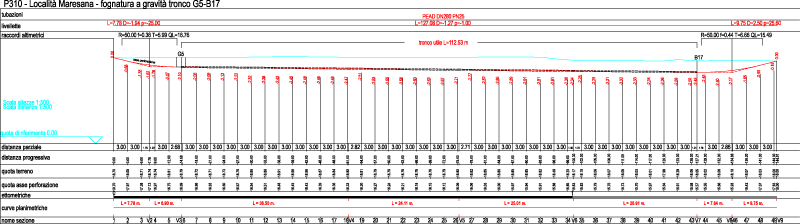

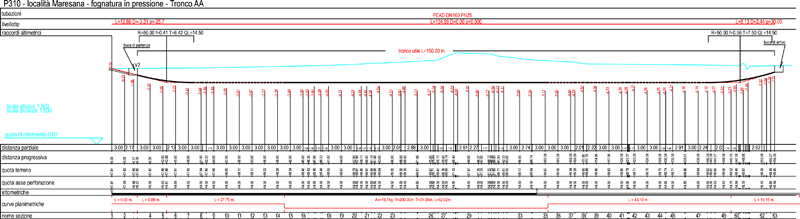

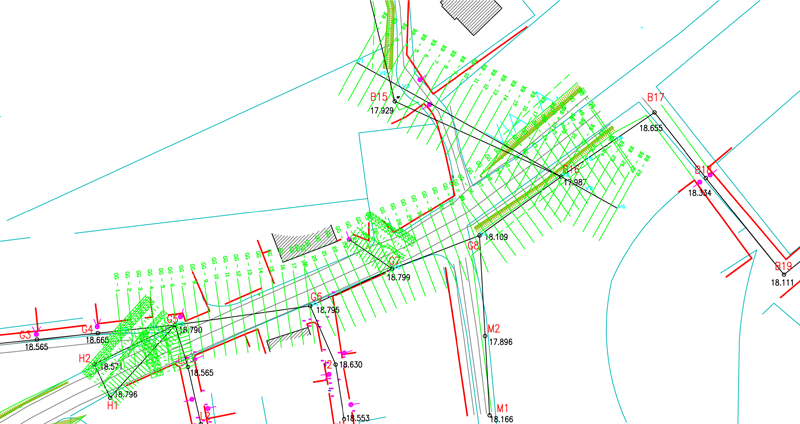

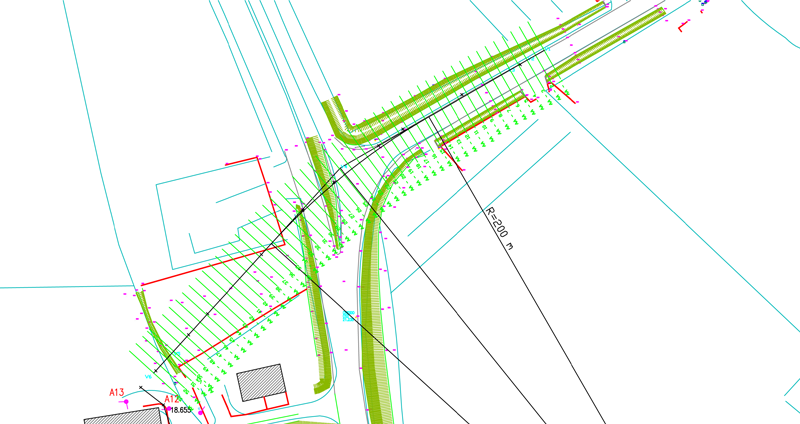

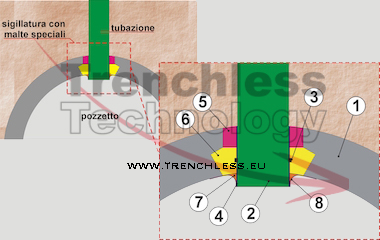

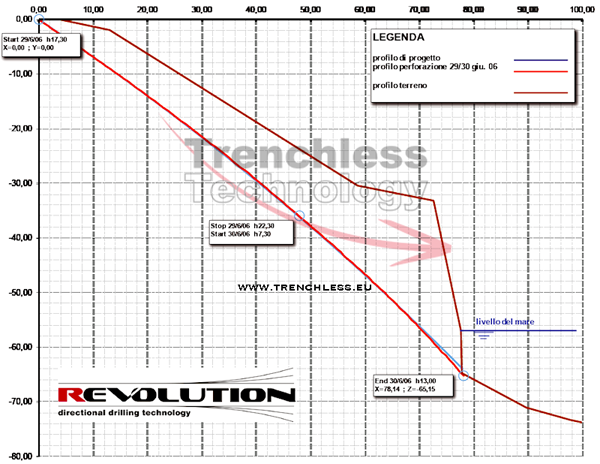

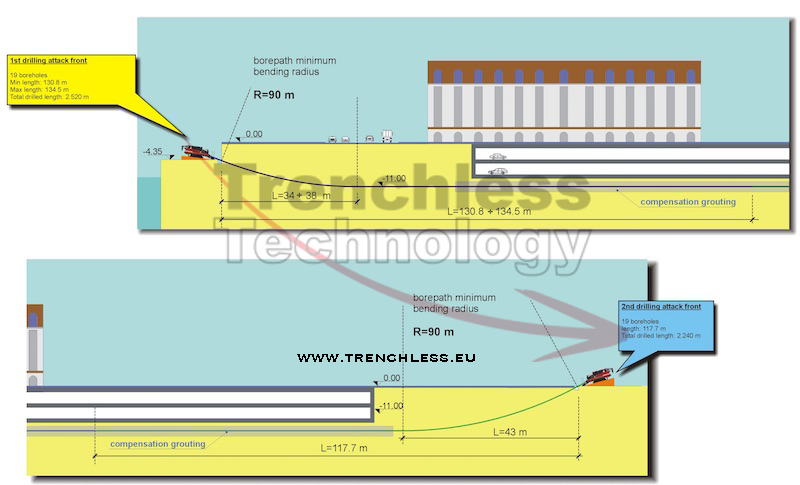

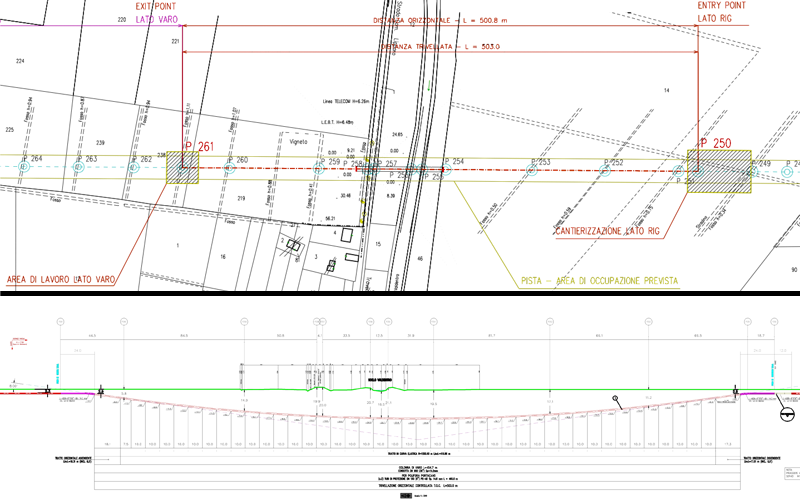

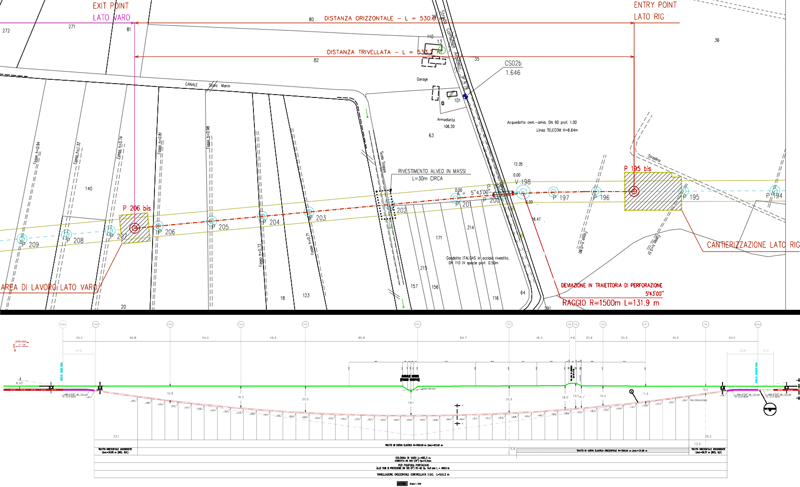

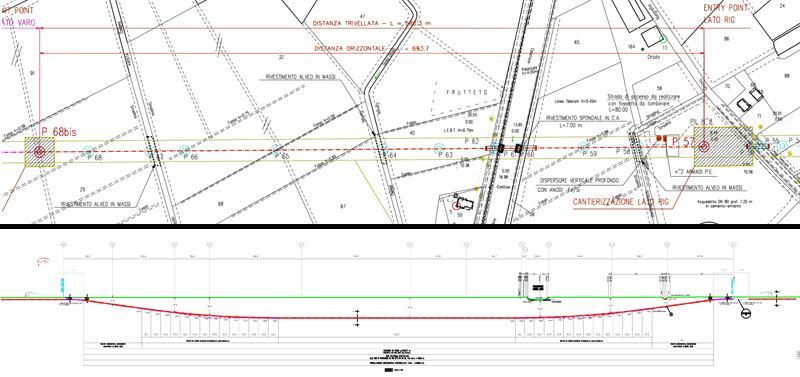

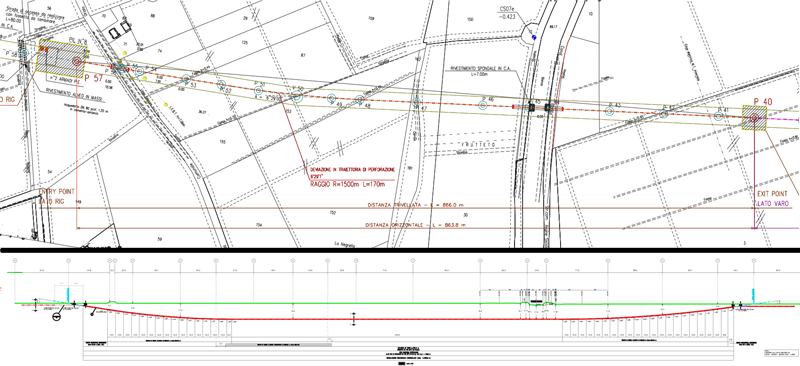

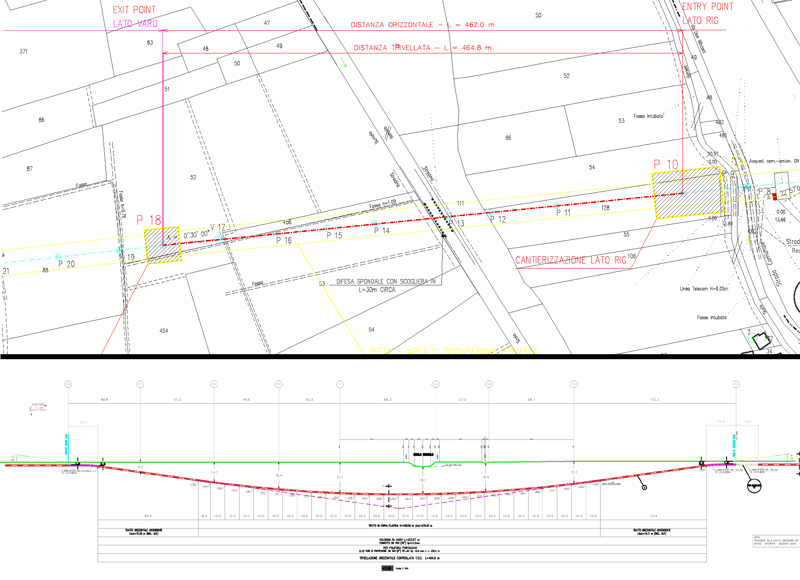

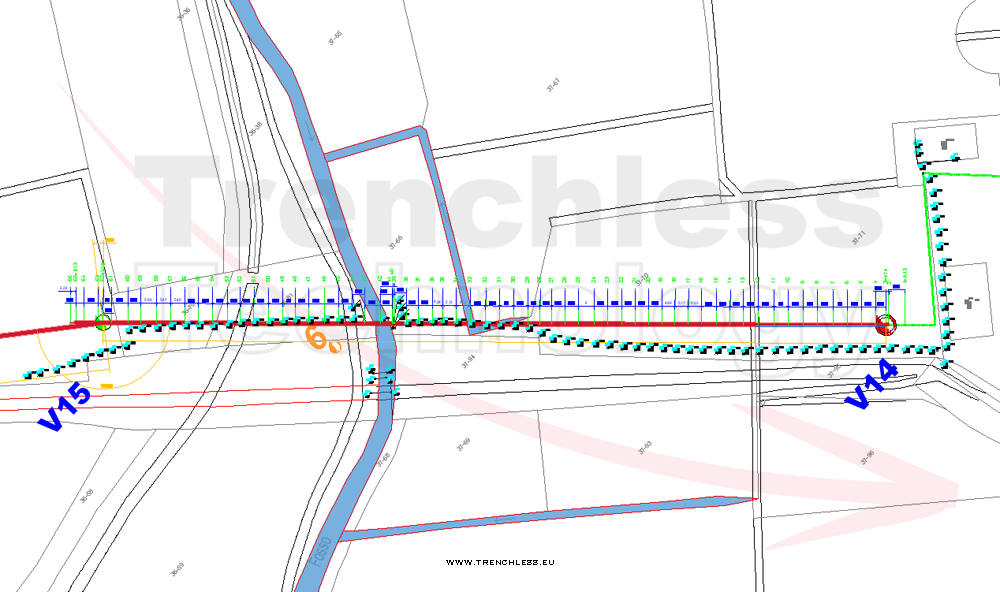

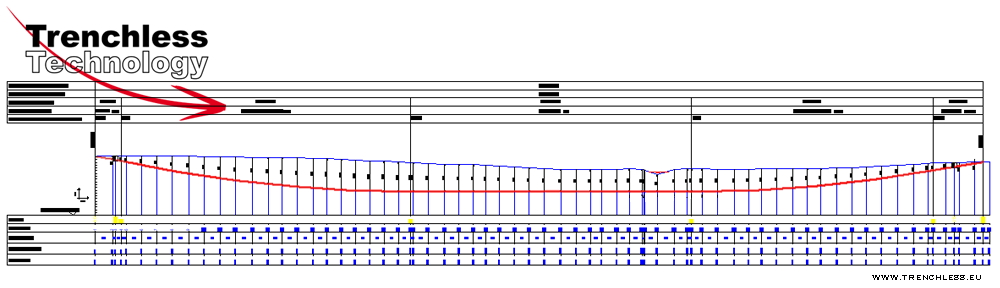

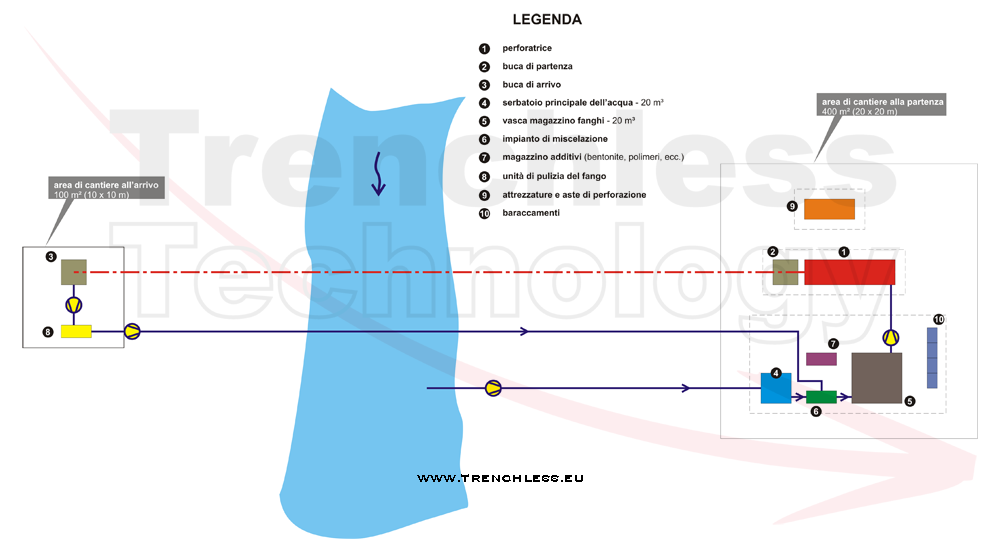

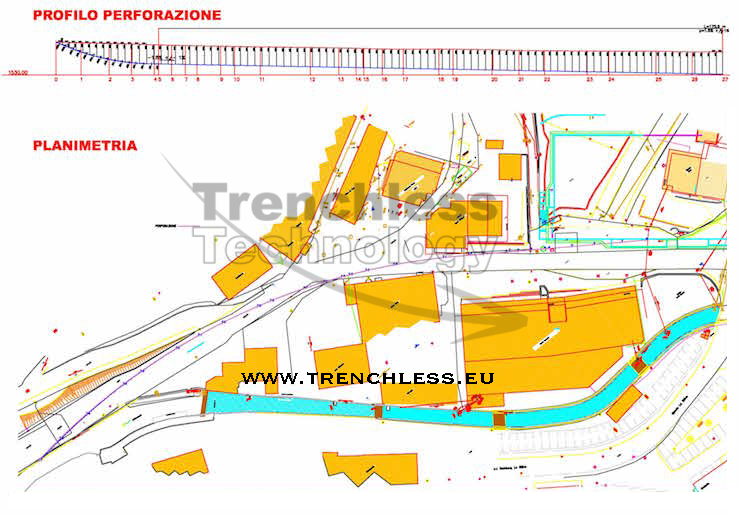

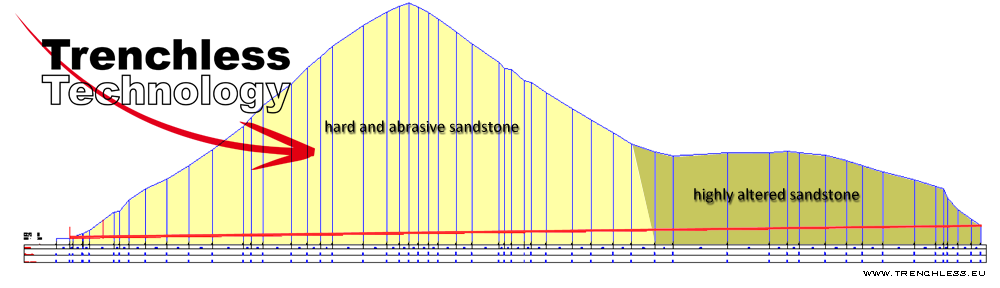

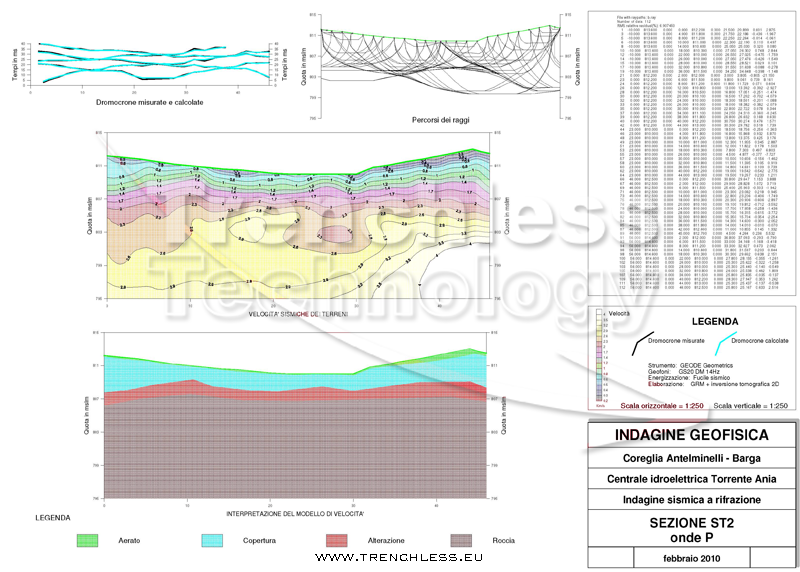

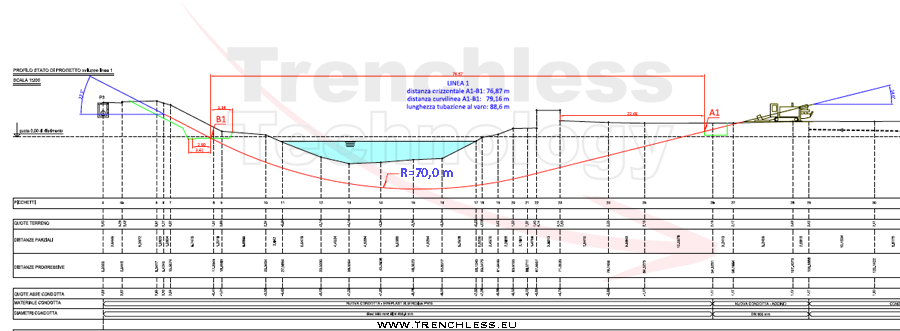

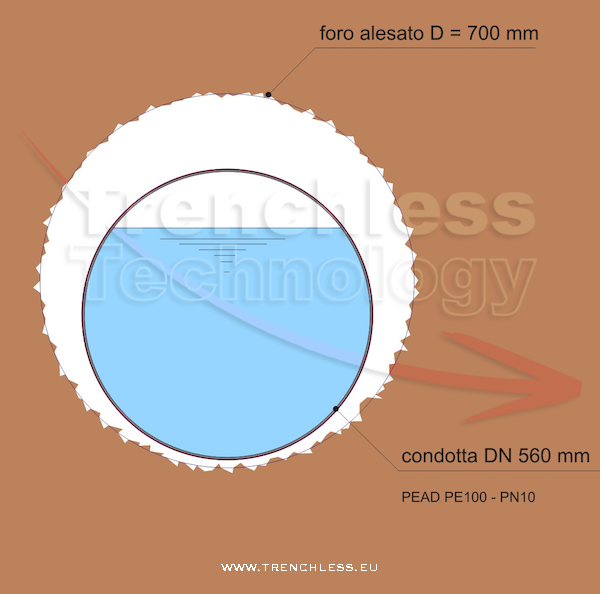

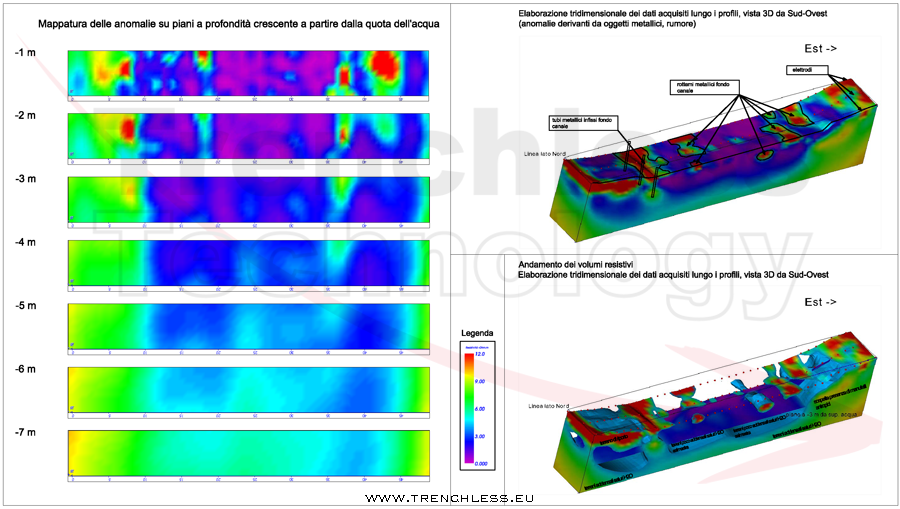

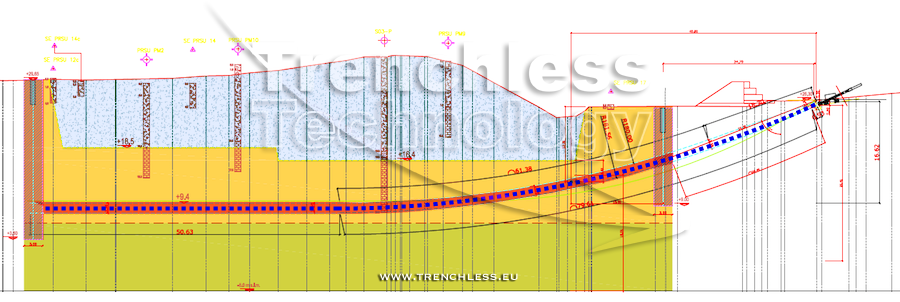

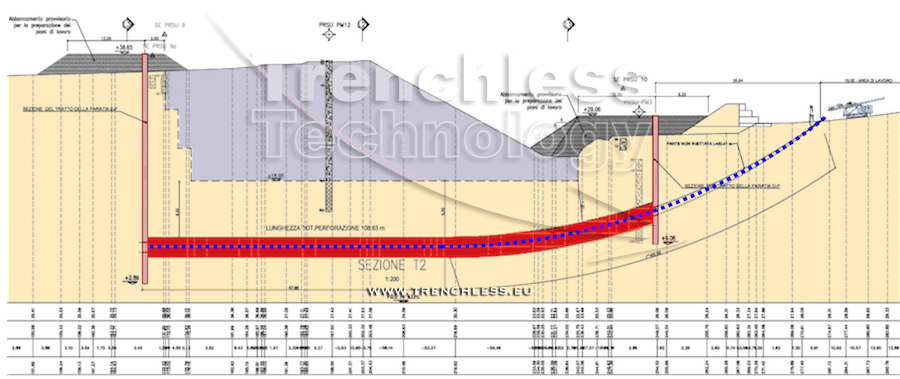

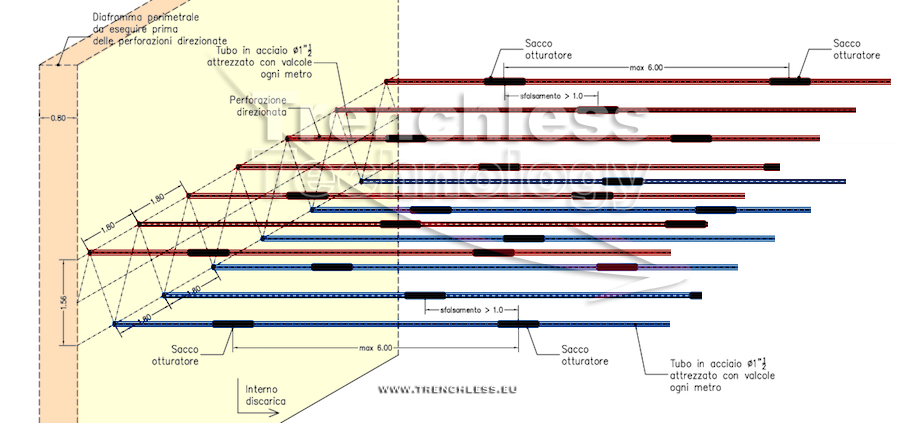

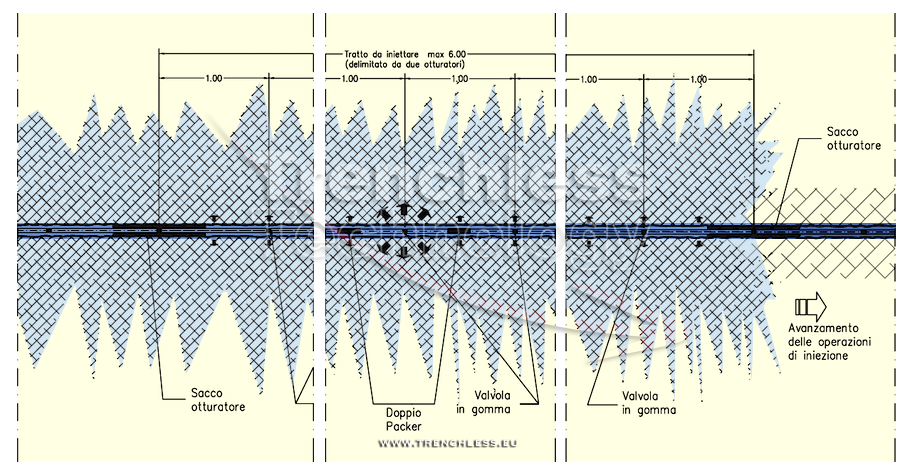

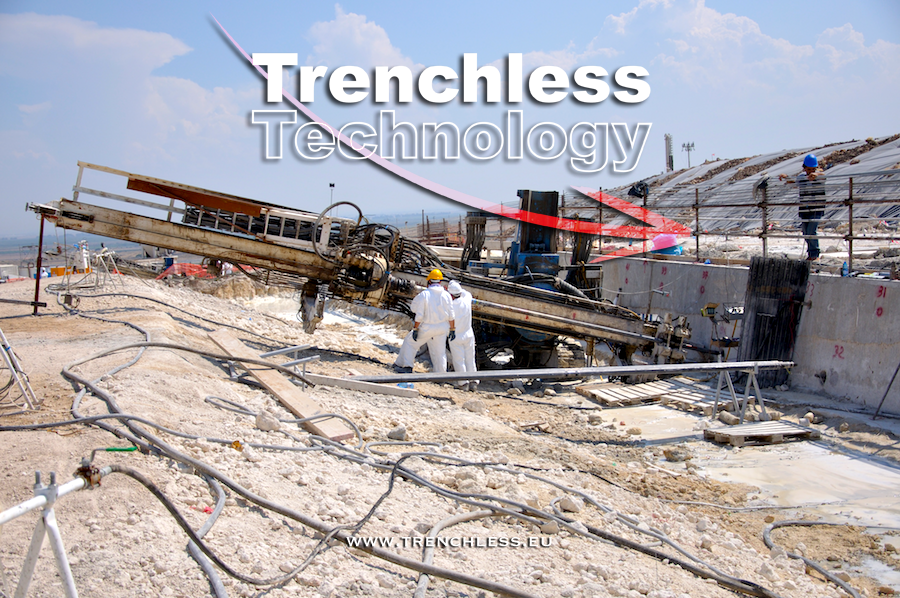

What I did: I made the detailed design of the installation of pressure and gravity sewer pipes by directional drilling; I carried on the training of the technical personnel (engineers, supervisors and operators). I developed a dedicated and complete HDD pit launched installation system for the connection of houses to the sewer mains. I also wrote two technical standards: the first for preliminary underground mapping and the second for the construction of house connections by using pit launched HDD machines.

click on the image to see the index of the standard norm (language: Italian)

click on the image to see the index of the standard norm (language: Italian)

Related documents:

- Directional Drilling – la tecnologia e le applicazioni prima parte – Le Strade n. 4 – April-05 – Italy

- Directional Drilling – la tecnologia e le applicazioni seconda parte – Le Strade – May-05 – Italy