Client: AC Srl Unipersonale – SIEMENS Spa – Italy

Year: 2011

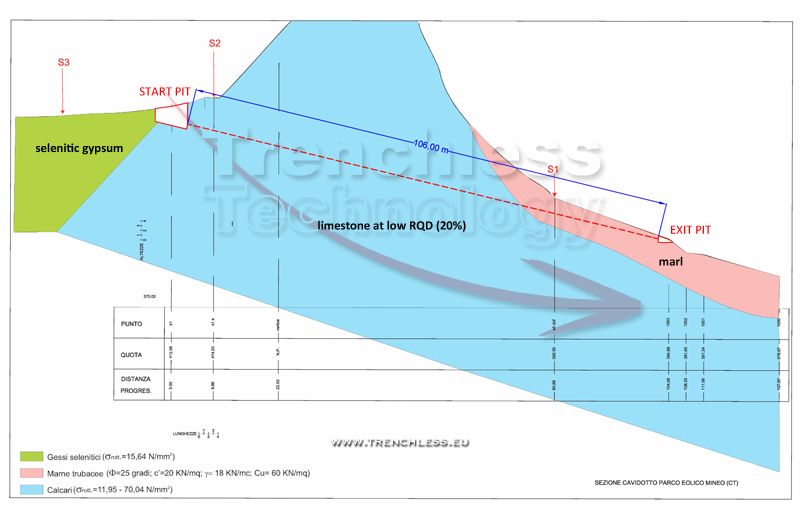

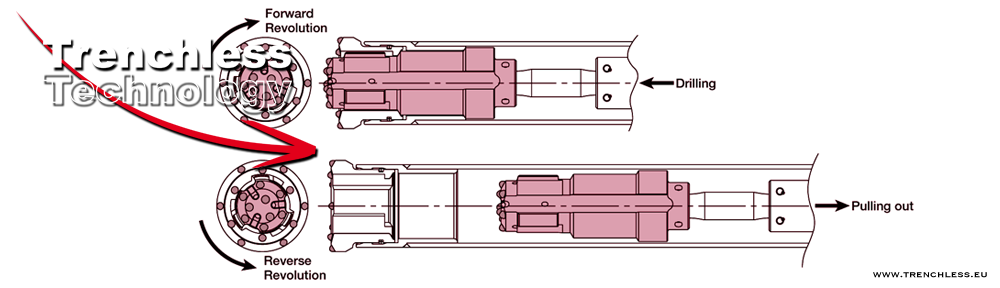

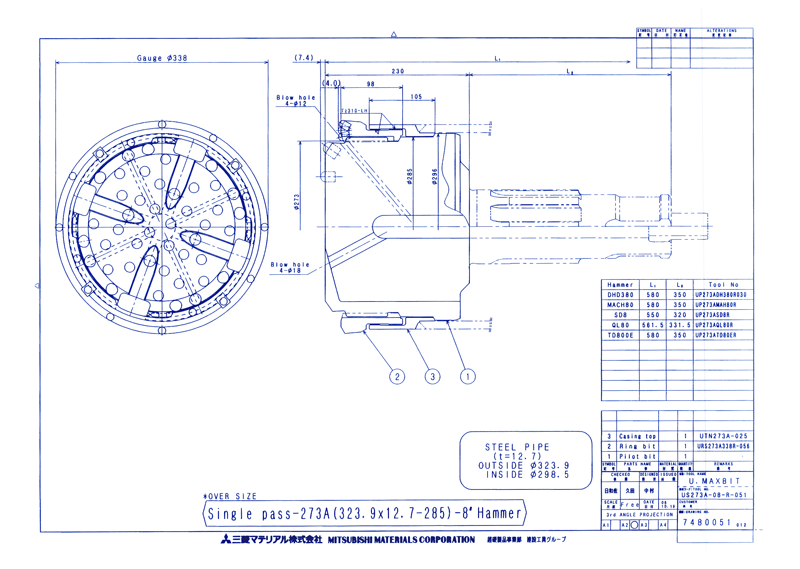

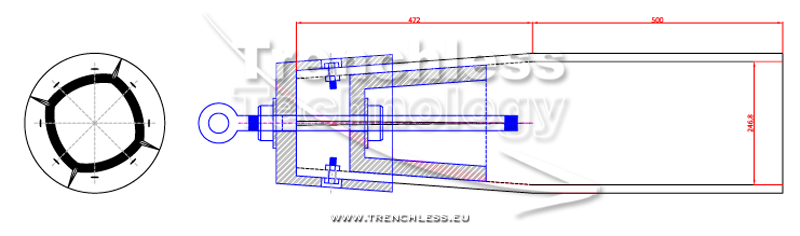

What I did: I made the detailed design and work supervision of the installation, by hybrid pipe jacking/down-the-hole concentric air hammer technique, of three DN300 (12”) steel casings and the installation, by slip-lining, inside the 12″ steel casings, of three HDPE DN280 (11″) pipes, for the crossing of a rocky hill – Length of each crossing: 106,0 meters. The HDPE DN280 pipes, installed inside the 12″ steel casings, were used by SIEMENS to lay hi-tension electrical cables. A MITSUBISHI ULTRA MAXBIT 12″ were used to perform the boreholes.