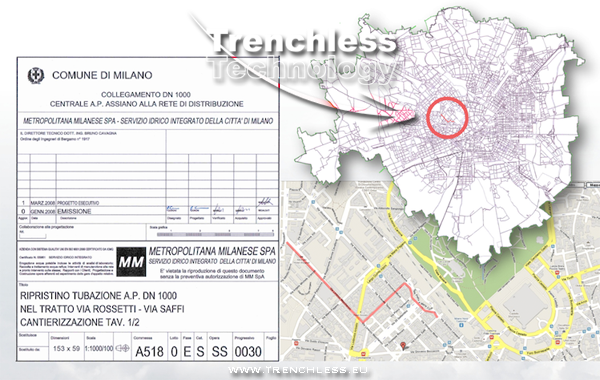

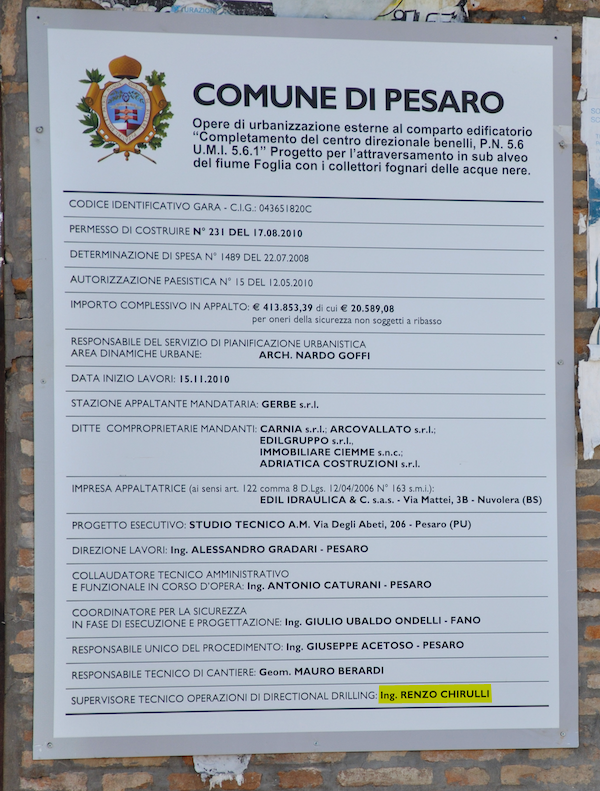

Client: TEA Spa – Italy

Year: 2011

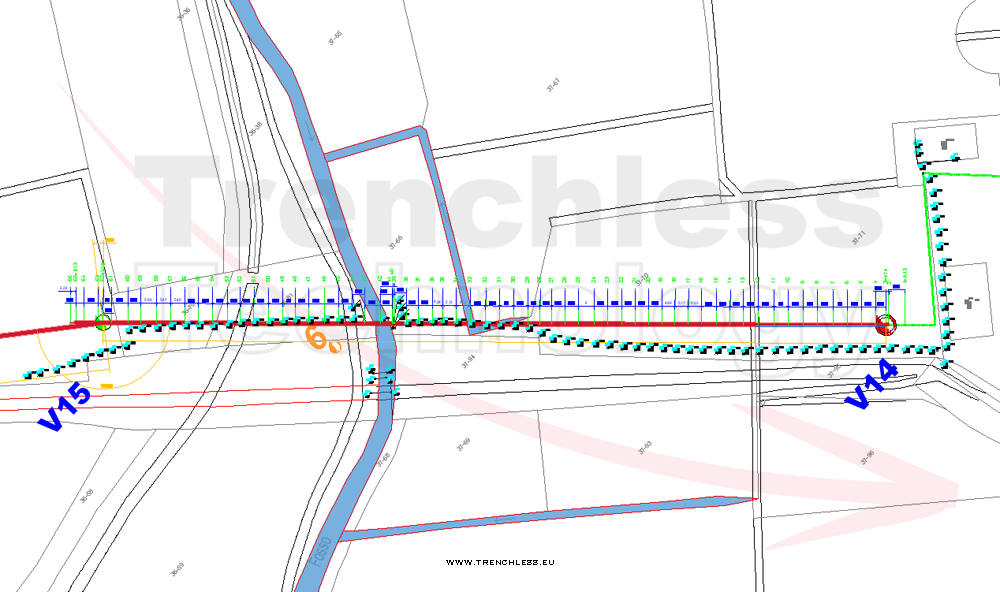

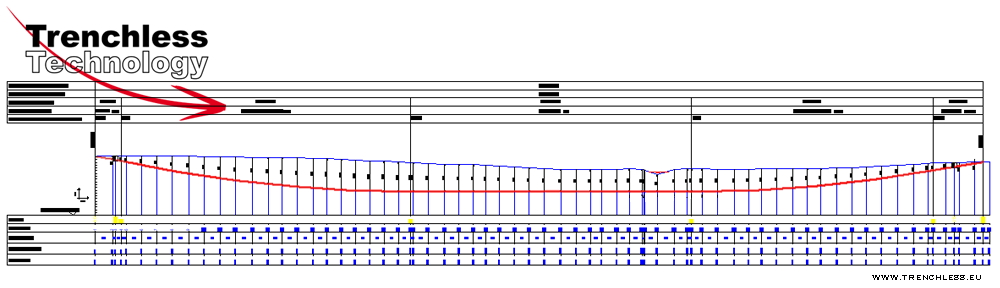

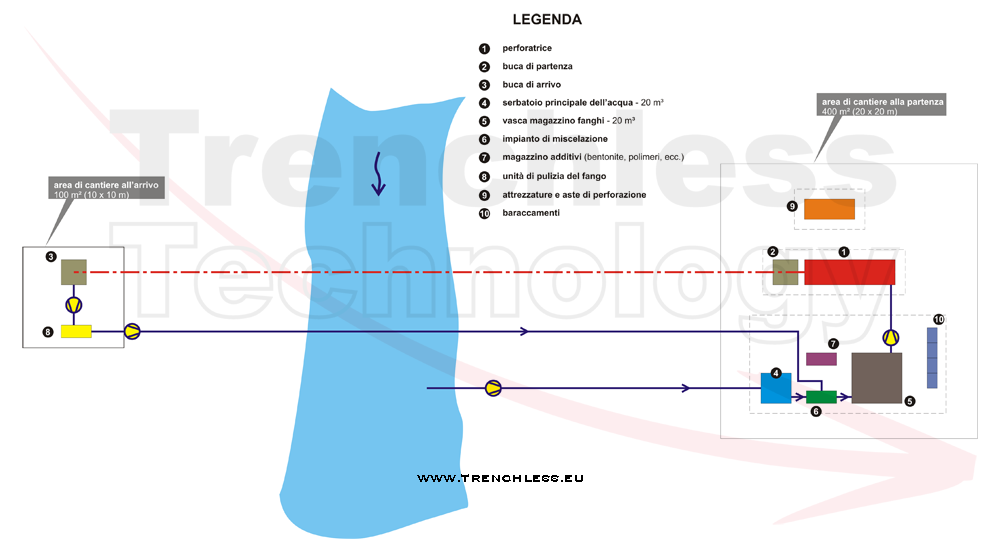

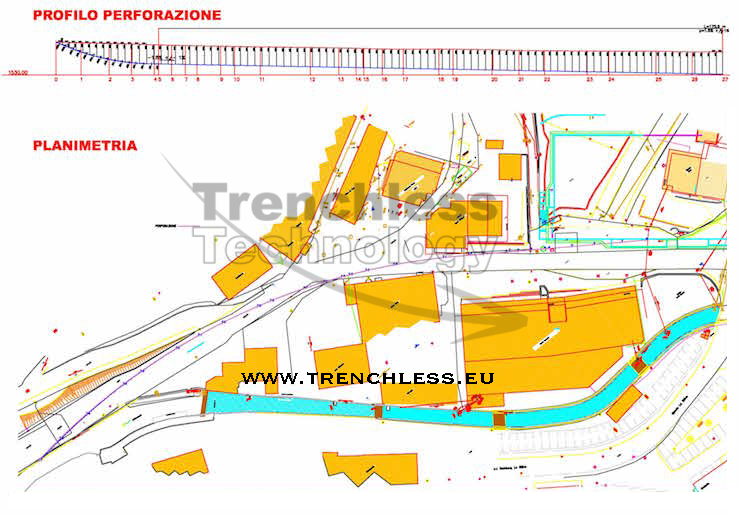

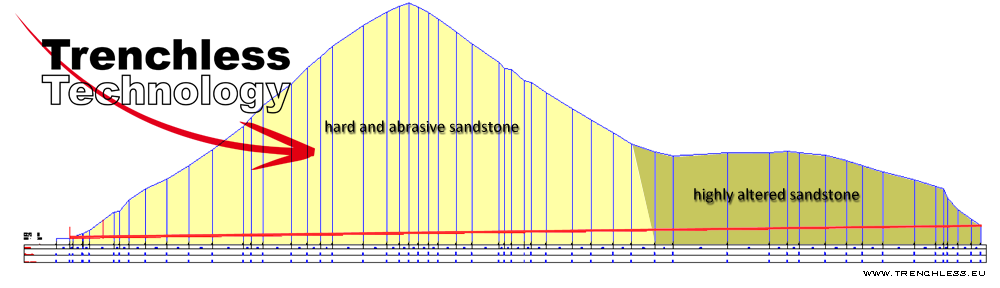

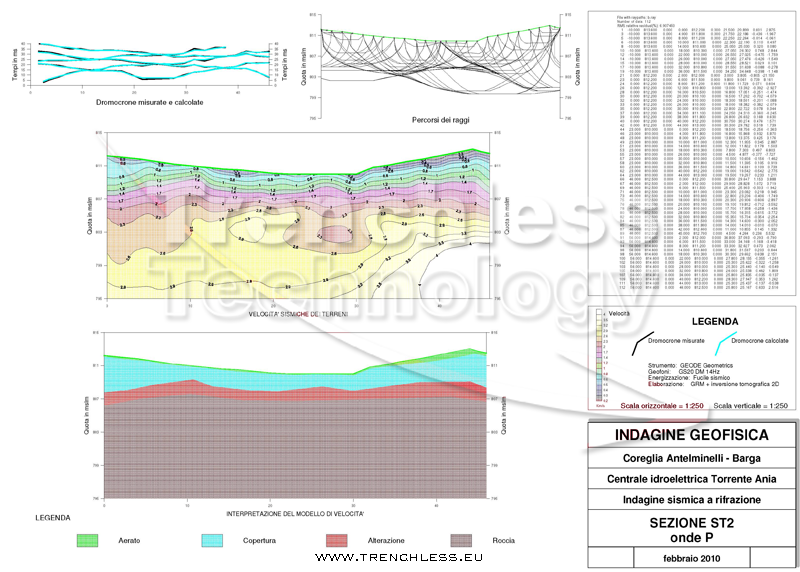

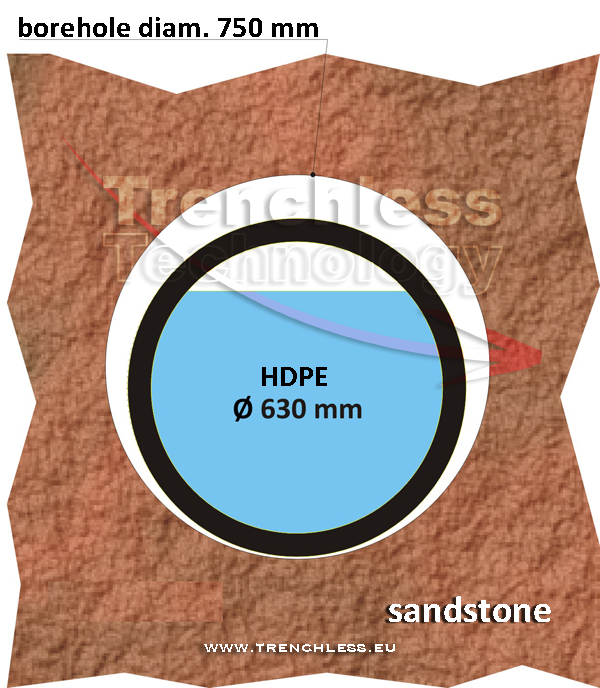

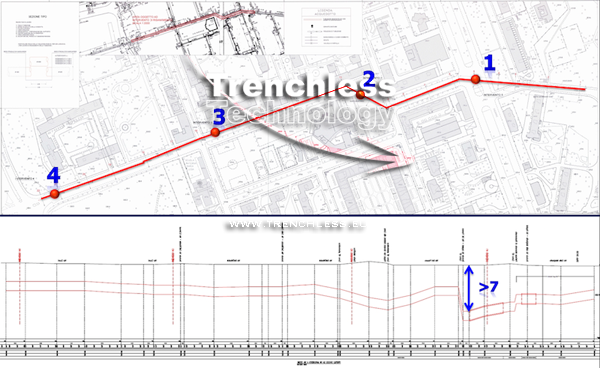

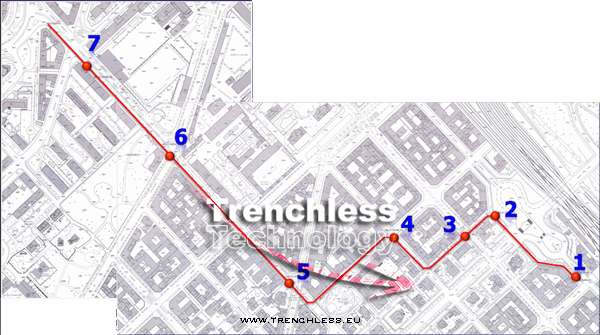

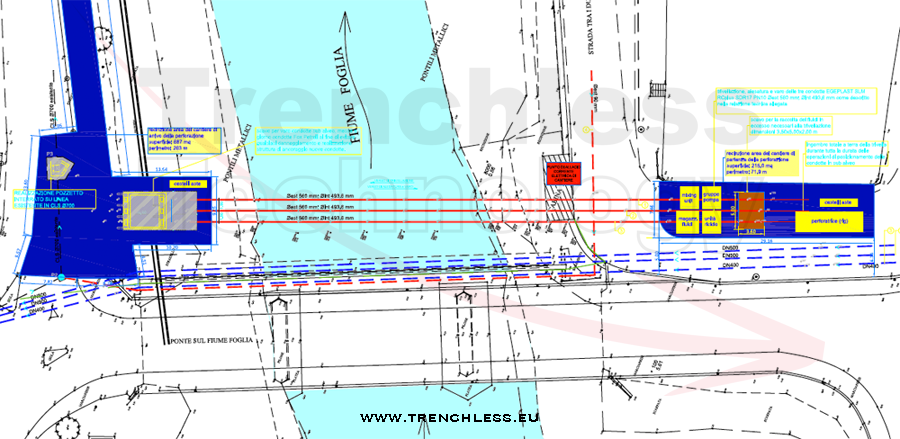

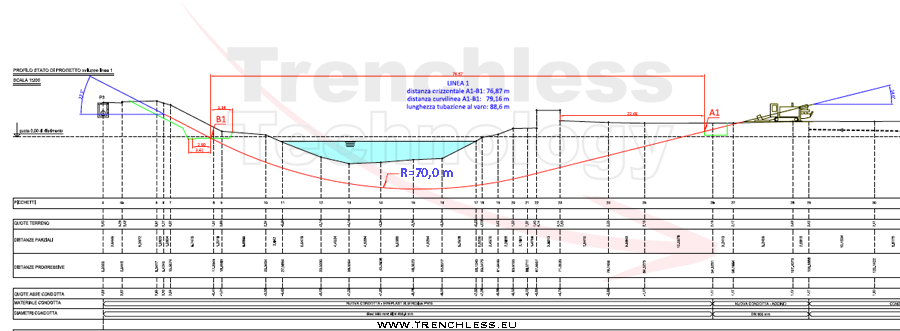

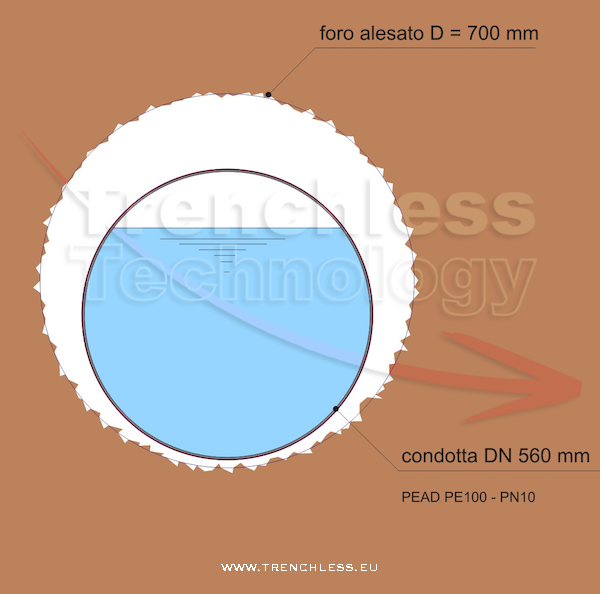

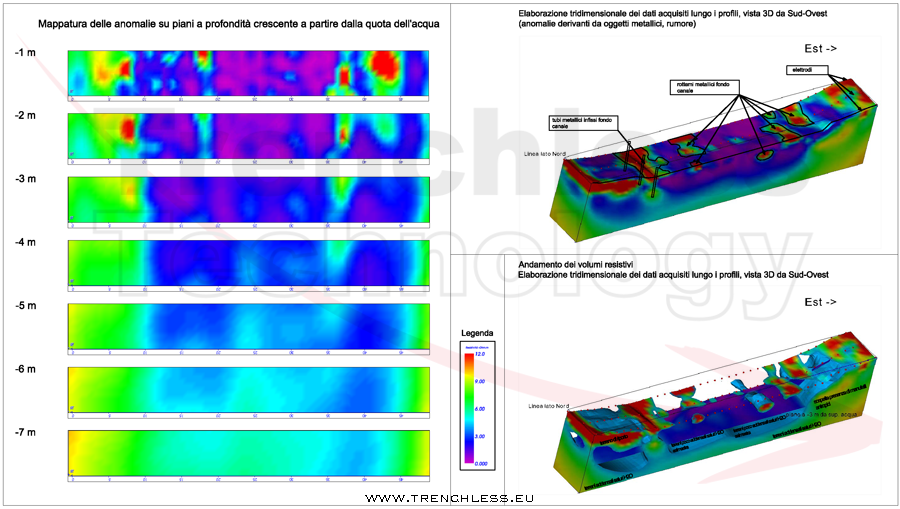

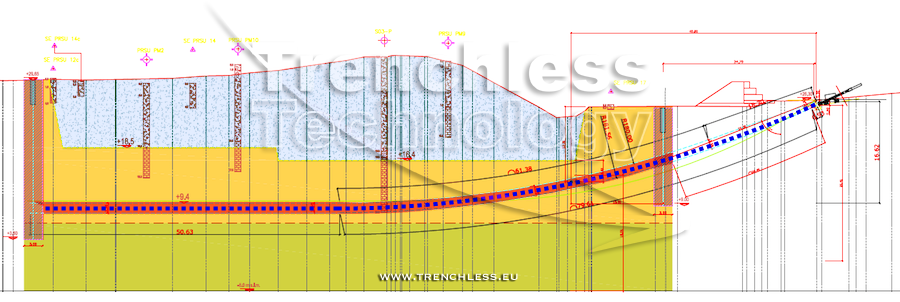

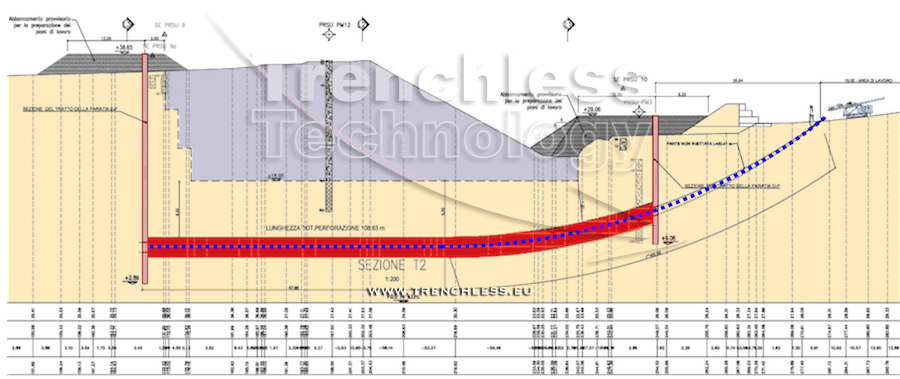

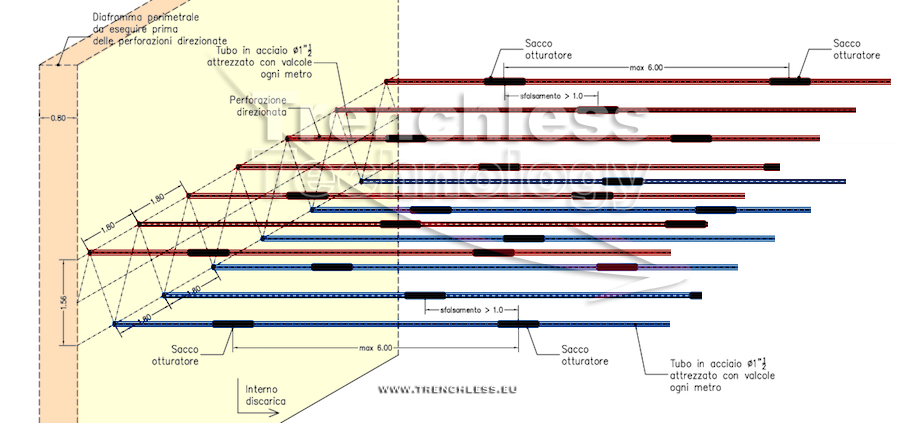

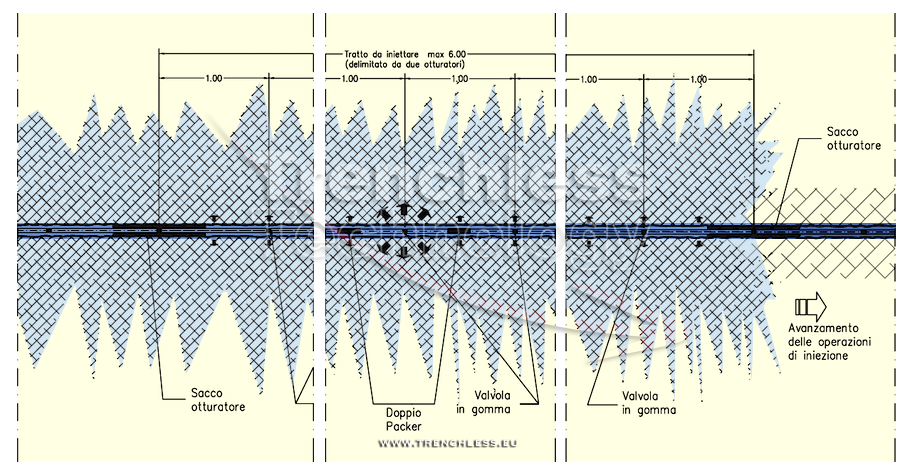

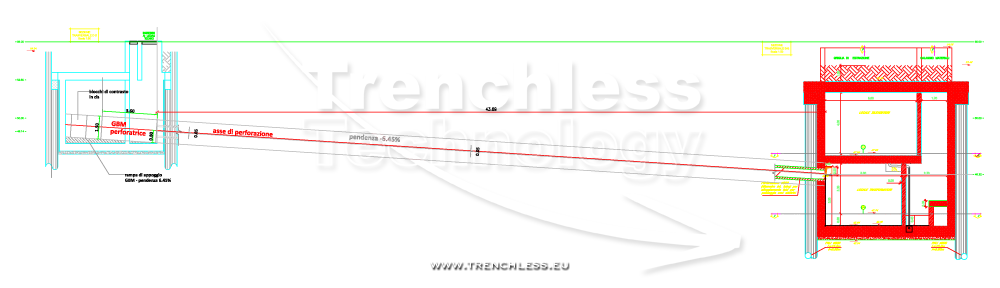

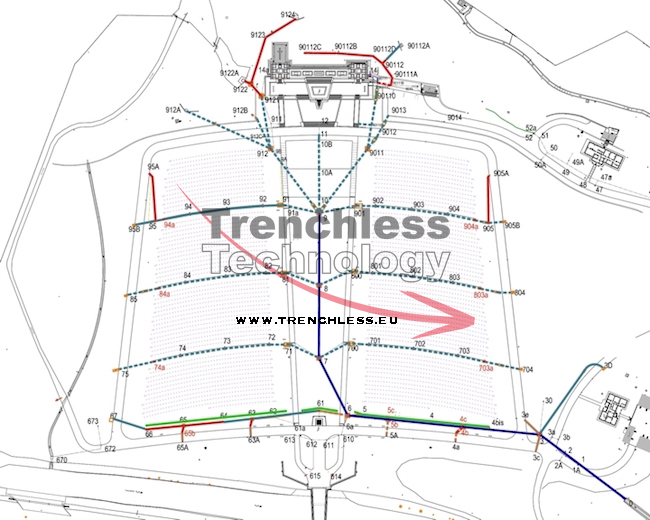

What I did: I made the detailed design of o channel crossing, by HDD, for the installation of a pressure sewer main for a total length of 320 m (1.000 ft); this project was part of a specialized training program that I carried out with the engineering personnel of the company and that led to the completion of the project of installation of the whole sewer main, entirely made by HDD, for a total length of 5,9 km (3,7 miles), divided in 21 HDD crossings.